Filters are essential in keeping air compressors running efficiently. Without them, your equipment may face serious problems. Pre-filters and post-filters serve different roles, but both are vital for clean air and protecting your system.

In this post, we'll explain the key differences between pre-filters and post-filters, helping you understand their importance and how they function.

2. What Is a Pre-Filter?

Definition

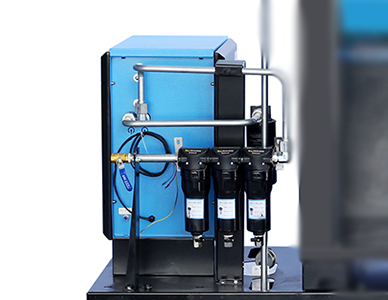

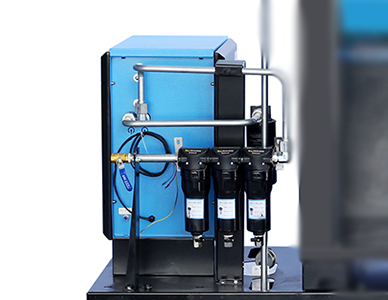

A pre-filter is the first line of defense in an air compressor system. It's located before the compressor intake or between the air tank and refrigeration dryer. Its primary job is to capture larger particles, moisture, and oil before they enter the compressor. This process prevents these contaminants from damaging internal components, keeping the system clean.

Role in the System

The pre-filter plays a critical role in protecting the compressor. By stopping larger debris like dust or sand, it ensures that these materials don’t cause internal wear or block airflow. Without it, these particles would enter the system, leading to equipment failure and costly repairs.

Common Contaminants Removed

Pre-filters are designed to handle:

Dust

Sand

Large particulates

Moisture

Oil mist

Benefits

Using a pre-filter brings multiple advantages:

Extend the lifespan: Preventing large particles from entering extends the life of key components.

Reduce maintenance costs: With less debris inside, fewer repairs and replacements are needed, saving money.

Improve performance: Keeping the air clean helps the system run more efficiently, ensuring better overall performance.

3. What Is a Post-Filter?

Definition

A post-filter is used in the final stages of air compression. It's located after the refrigeration dryer, where air has already been cooled and partially cleaned. Its job is to filter out smaller, more fine contaminants that remain in the air, ensuring the output is clean and dry. Post-filters are key in applications that require high air purity.

Role in the System

The post-filter serves to protect the end-use equipment by refining the air quality. It removes ultra-fine particles and any remaining moisture, ensuring that the air meets strict quality standards. Without it, equipment downstream could be damaged by residual oil, water, or fine particles, leading to malfunctions.

Common Contaminants Removed

Post-filters are designed to capture very fine impurities, including:

These contaminants, though small, can greatly affect equipment performance if not removed.

Benefits

The post-filter is essential for ensuring the cleanest possible air, especially in precision-demanding applications. Post-filters provide several key benefits:

Ensure high-quality output: They purify the compressed air to meet specific industry standards.

Protect sensitive equipment: Post-filters help keep tools and machinery in optimal condition by removing damaging particles.

Reduce downtime: Cleaner air reduces equipment failure, saving time on repairs.

Improve product quality: In industries like pharmaceuticals or food processing, air purity directly affects the end product.

4. Key Differences Between Pre-Filters and Post-Filters

Functionality

Pre-filters and post-filters serve different roles in an air compressor system. Pre-filters are responsible for removing large contaminants like dust, moisture, and oil from the intake air before it enters the compressor. This prevents the system from becoming clogged or damaged by large debris. Post-filters, however, clean the compressed air by removing smaller particles such as oil mist, fine dust, and water vapor. This ensures the air is pure and suitable for sensitive equipment.

Location

Pre-filters are typically installed at the air intake, where they capture contaminants before they can enter the compressor. Their strategic placement protects the compressor from damage. On the other hand, post-filters are located downstream, after the compression process, close to the equipment using the air. This ensures the air is clean and ready for use in industries that require high air purity.

Filtration Precision

Pre-filters have a lower filtration precision compared to post-filters. They can filter particles between 1-5 microns, which is effective for larger contaminants such as dust and sand. Post-filters, by contrast, offer finer filtration, capturing particles as small as 0.01 microns. This high level of precision is crucial for removing oil mist, water vapor, and very fine dust particles, making the air safe for specialized applications.

| Filter Type | Particle Size Captured | Common Contaminants |

| Pre-Filter | 1-5 microns | Dust, sand, large particulates |

| Post-Filter | 0.01-1 microns | Fine dust, oil mist, moisture |

Impact on Equipment

Pre-filters primarily protect the compressor itself, preventing large contaminants from causing wear or damage. Without them, the system could face significant maintenance issues. Post-filters protect downstream equipment, ensuring that the air used by end-user machinery or tools is free from harmful fine particles. Clean air from post-filters helps reduce equipment failure and increases longevity.

Cost Considerations

The cost of maintaining both filters varies. Pre-filters are generally cheaper due to their simpler construction, but require more frequent replacement. Post-filters offer higher filtration accuracy, tend to cost more, and have longer replacement intervals. Neglecting either filter can result in significant expenses, including equipment failure, increased energy consumption, and production delays.

Requirements of Air Quality

Post-filters are indespensible in industries where high air purity is required, such as food production, pharmaceuticals, or electronics. These industries rely on extremely clean, dry air to maintain product quality and meet regulatory standards. Pre-filters are less critical for air purity but essential for protecting the compressor from large contaminants.

In summary, pre-filters remove large particles before air enters the compressor, while post-filters clean compressed air of finer impurities. They serve different functions but are closely connected. Both are essential for protecting equipment and ensuring air quality. Please keep in mind that regular filter checks are key to keeping your system efficient and reliable in the long run. Aivyter's expert team is available to provide personalized maintenance services, ensuring your system runs efficiently. If you have any questions about air fliter, reach out to us today for professional guidance and support.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara