Product Introduction

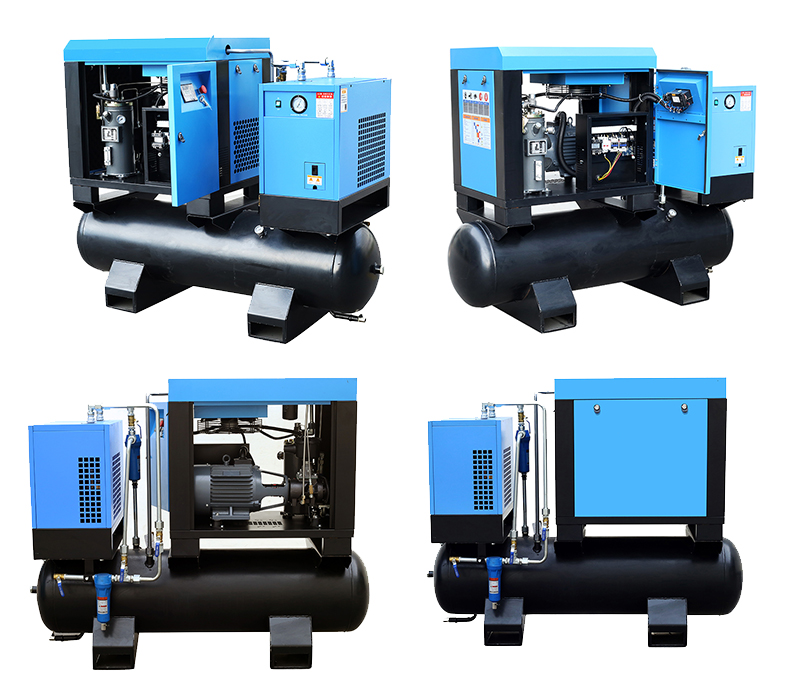

Introducing the 11kW 15Hp Combined Direct Drive Screw Type Air Compressor With 300l Air Tank - the perfect solution for your compressed air needs. This industrial-grade air compressor is designed to deliver reliable and efficient performance, making it an ideal choice for a variety of applications.

At the heart of this air compressor is a direct drive screw type compressor that delivers high efficiency and stability. With a maximum pressure, this compressor can handle even the most demanding compressed air applications. The 300l air tank ensures a steady supply of compressed air, allowing you to work uninterrupted for longer periods.

This air compressor is also designed with energy efficiency and environmental friendliness in mind. The low noise and vibration motor, optimized cooling system, and energy-saving features ensure that this compressor not only consumes less power but also operates quietly and with minimal impact on the environment.

The durability and maintenance of this air compressor are also noteworthy. With a long lifespan and minimal maintenance requirements, this compressor can provide reliable performance for years to come. The recommended maintenance schedule is easy to follow, ensuring that your air compressor continues to operate at peak performance.

We stand behind the quality of our products and offer excellent after-sales service to our customers. With our commitment to customer satisfaction, you can trust that you are getting a high-quality product that will meet your compressed air needs.

Invest in the 11kW 15Hp Combined Direct Drive Screw Type Air Compressor With 300l Air Tank for reliable, efficient, and environmentally friendly compressed air.

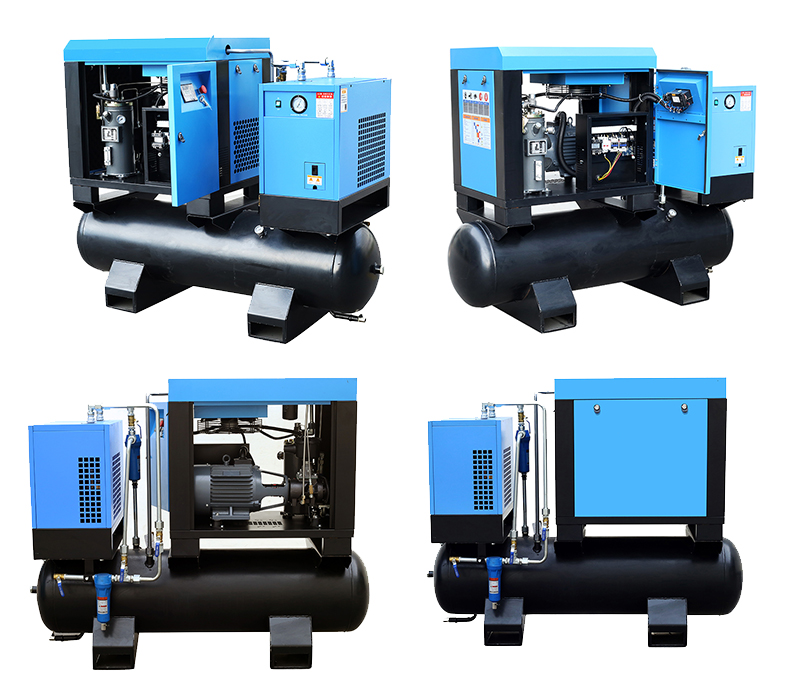

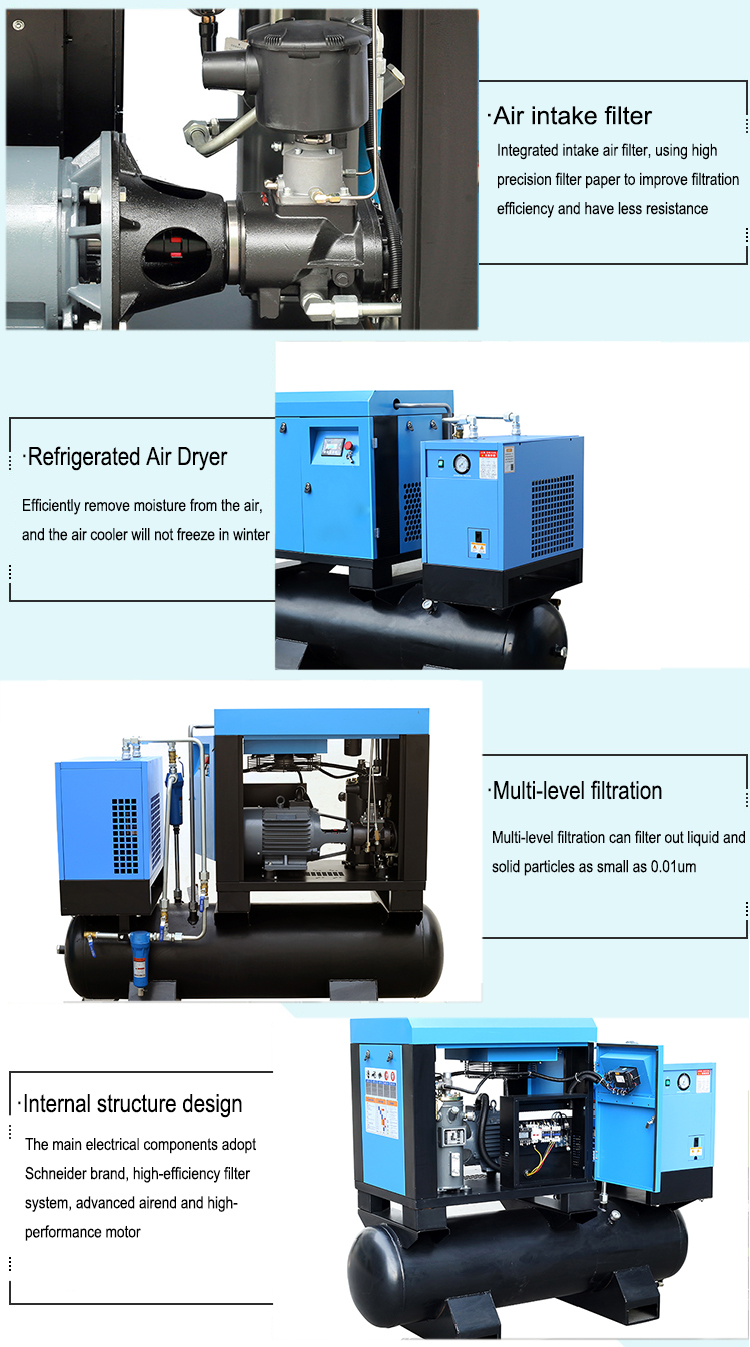

Product Details: Integrated Type Screw Air Compressor

The integrated screw air compressor combines multiple components into one unit. It includes a screw air compressor, freeze dryer, precision filter, and air storage tank. This design simplifies installation and operation. The system's mobility allows for easy relocation. The integrated process enhances air quality, meeting diverse industrial requirements. This solution serves various enterprise needs efficiently.

Features of 11kW 15Hp Combined Direct Drive Screw Type Air Compressor with 300L Air Tank

Integrated Design Products

Fewer parts and connectors, minimizing failure and leakage risks.

Integrated piping system reduces pressure loss effectively.

Ensures high-quality air output by eliminating dry compressed air.

Space-saving design with an integrated compressor, dryer, and filter.

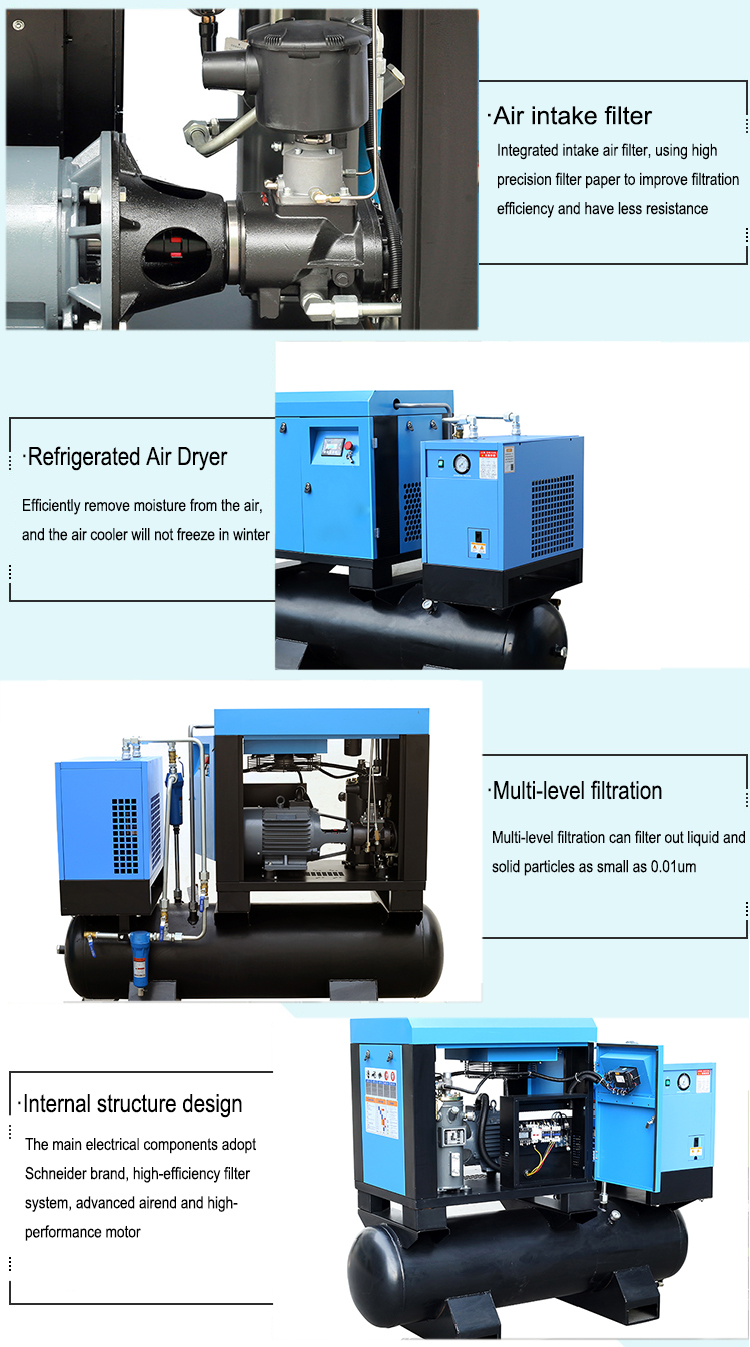

High-Performance Cold Dryer

Uses eco-friendly refrigerants like R134A and R410A.

Compact design with high-cooling capacity for efficient operation.

Reliable performance in high-temperature conditions.

Control Panel

Control System

High-Quality Special Motor

Equipped with SKF bearings for durability.

Features Class F insulation for enhanced motor protection.

OEM voltage options with IP23/IP54 and permanent magnet motor compatibility.

Low Noise

High-elastic shock mounts reduce vibration.

Flame-retardant polyurethane for noise reduction.

Double air duct design for quieter operation.

Oil Injection Separation System

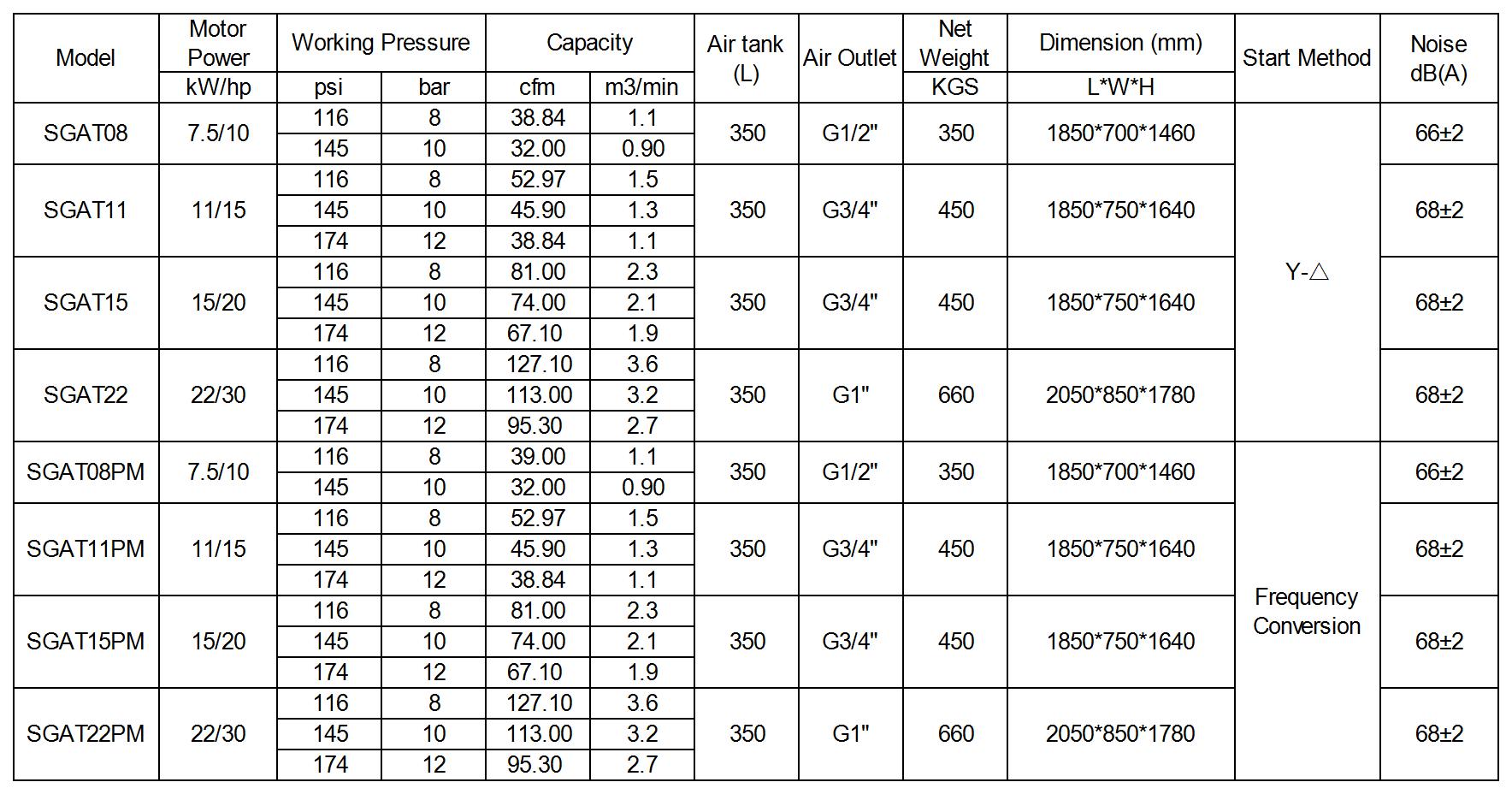

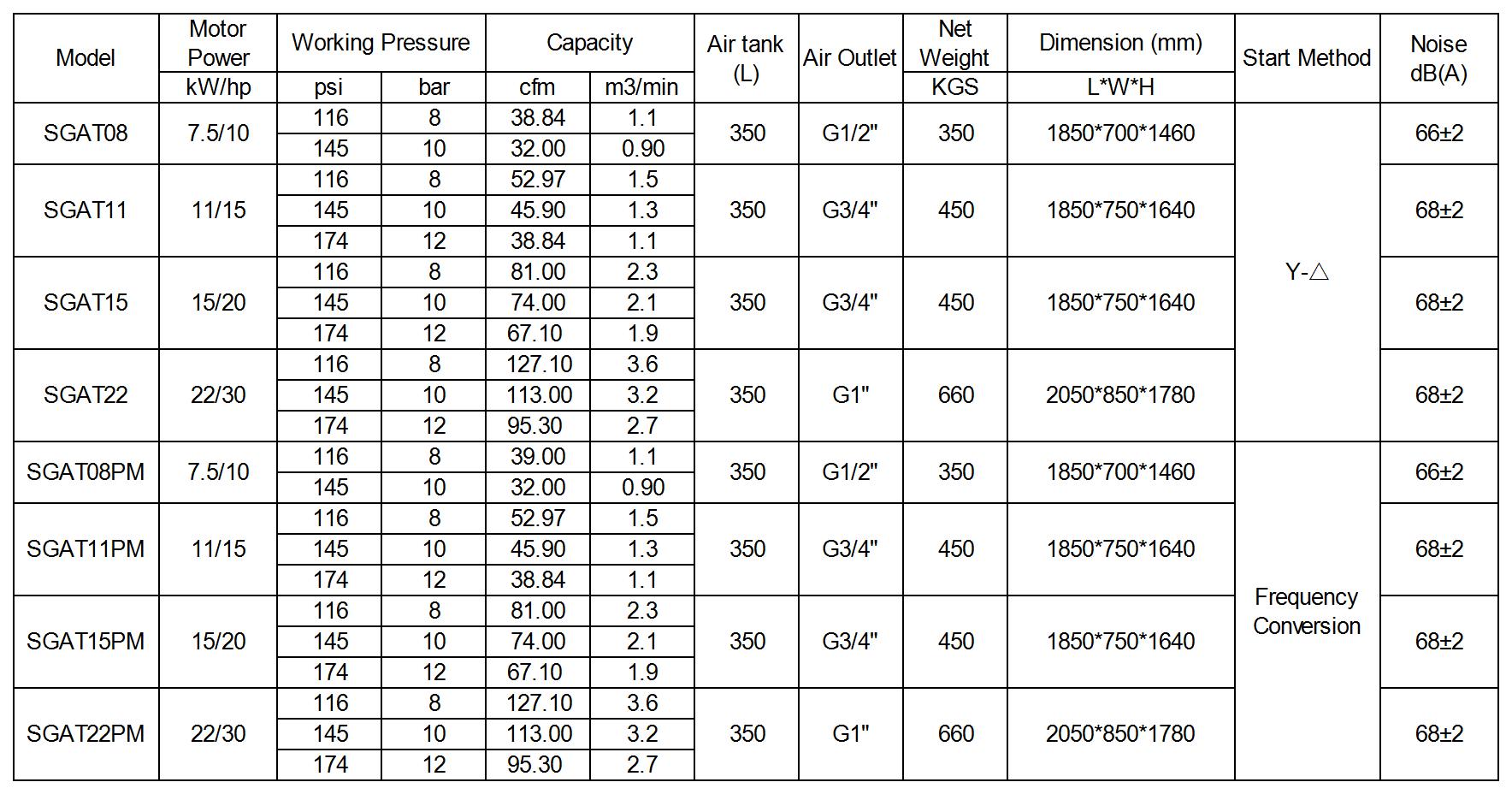

Product Specifications:

Fujian Aivyter Compressor Co., Ltd., was established in 2011, and located in Fuzhou China, is a professional enterprise engaged in the research, development, sale and service of screw air compressor, oil free screw air compressor, portable diesel engine screw air compressor, air dryer, precision filters, gas generator, gas booster compressor and engineering construction equipment.

FAQ:

Q1: What is the rotor speed for the air end?

A1: 2980rmp.

Q2: What's your lead time?

A2: usually, 5-7 days. (OEM orders: 15days)

Q3: Can you offer water cooled air compressor?

A3: Yes, we can (normally, air cooled type).

Q4: What's the payment term?

A4: T/T, L/C, Western Union, etc. Also we could accept USD, RMB, and other currency.

Q5: Do you accept customized voltage?

A5: Yes. 380V/50Hz/3ph, 380V/60Hz/3ph, 220V/50Hz/3ph, 220V/60Hz/3ph, 440V/50Hz/3ph, 440V/60Hz/3ph, or as per your requests.

Q6: What is your warranty for air compressor?

A6: One year for the whole air compressor(not including the consumption spare parts) and technical supports can be provided according to your needs.

Q7: Can you accept OEM orders?

A7: Yes, OEM orders are warmly welcome.

Q8: How about your customer service and after-sales service?

A8: 24hrs on-line support, 48hrs problem solved promise.

Q9: Do you have spare parts in stock?

A9: Yes, we do.

Q10: What kind of initial lubrication oil you used in air compressor?

A10: TOTAL 46# mineral oil.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara