Permanent magnet variable frequency rotary screw air compressor

Advanced permanent magnet technology: aivyter's air compressors are equipped with advanced permanent magnet frequency conversion technology and high-efficiency permanent magnet motors, which can provide efficient and reliable performance. The use of advanced magnets ensures consistent power output, reduces energy consumption, and extends service life.

Variable Frequency Drive (VSD): The compressor adopts a variable frequency drive, which can accurately control air pressure and flow rate. This adaptability ensures optimal performance for wide applications and helps maintain a constant pressure level, thereby improving the overall efficiency of the system.

Energy saving rotary screw design: The rotary screw mechanism is known for its efficiency in converting power into compressed air. Our design minimizes energy loss and ensures continuous and uninterrupted supply of compressed air.

Intelligent Control System: Our air compressor combines an intelligent control system, providing user-friendly operation and advanced diagnostic and mobile app monitoring functions. This system allows for remote monitoring to ensure that the compressor operates at maximum efficiency and reliability for 24 hours.

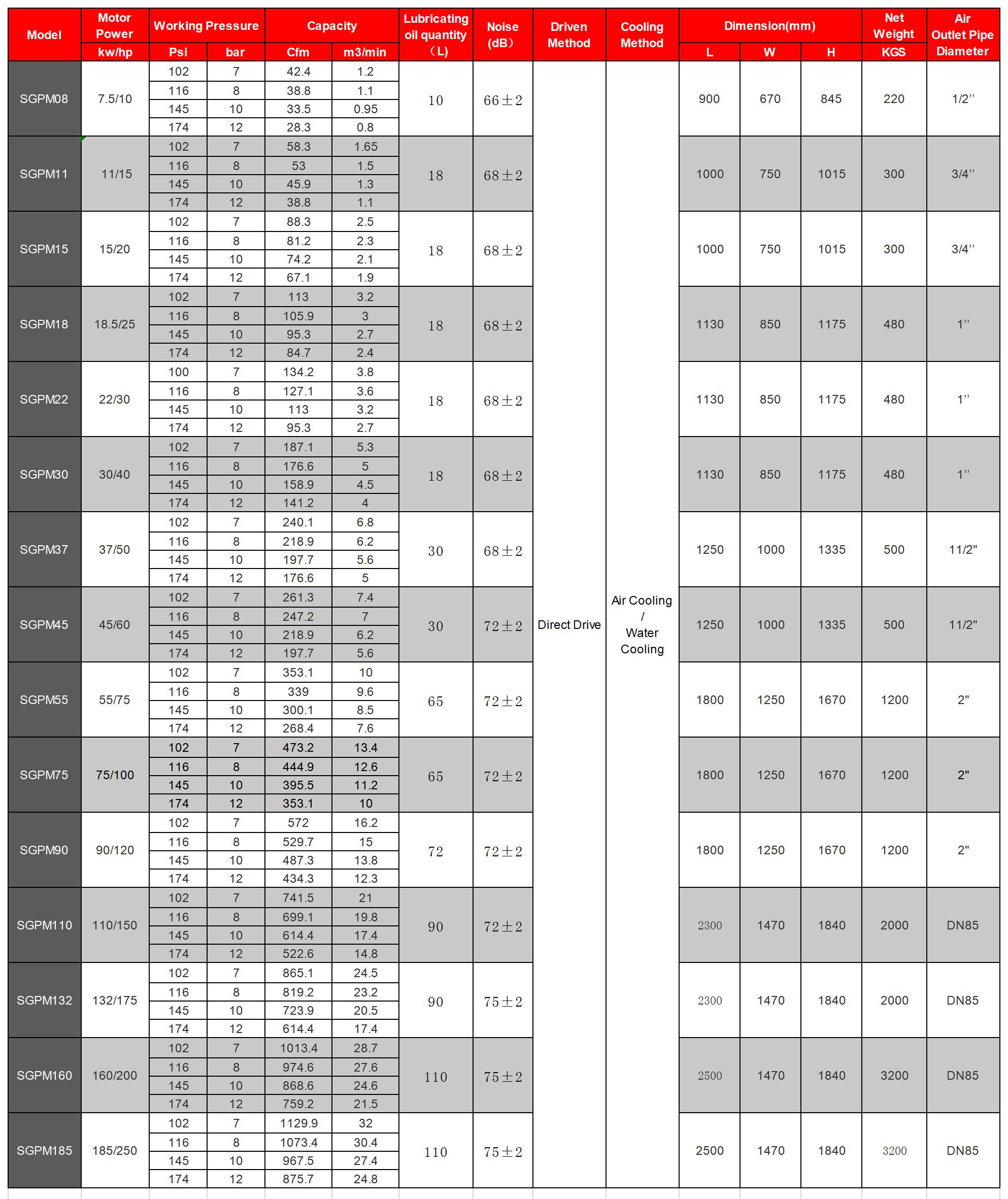

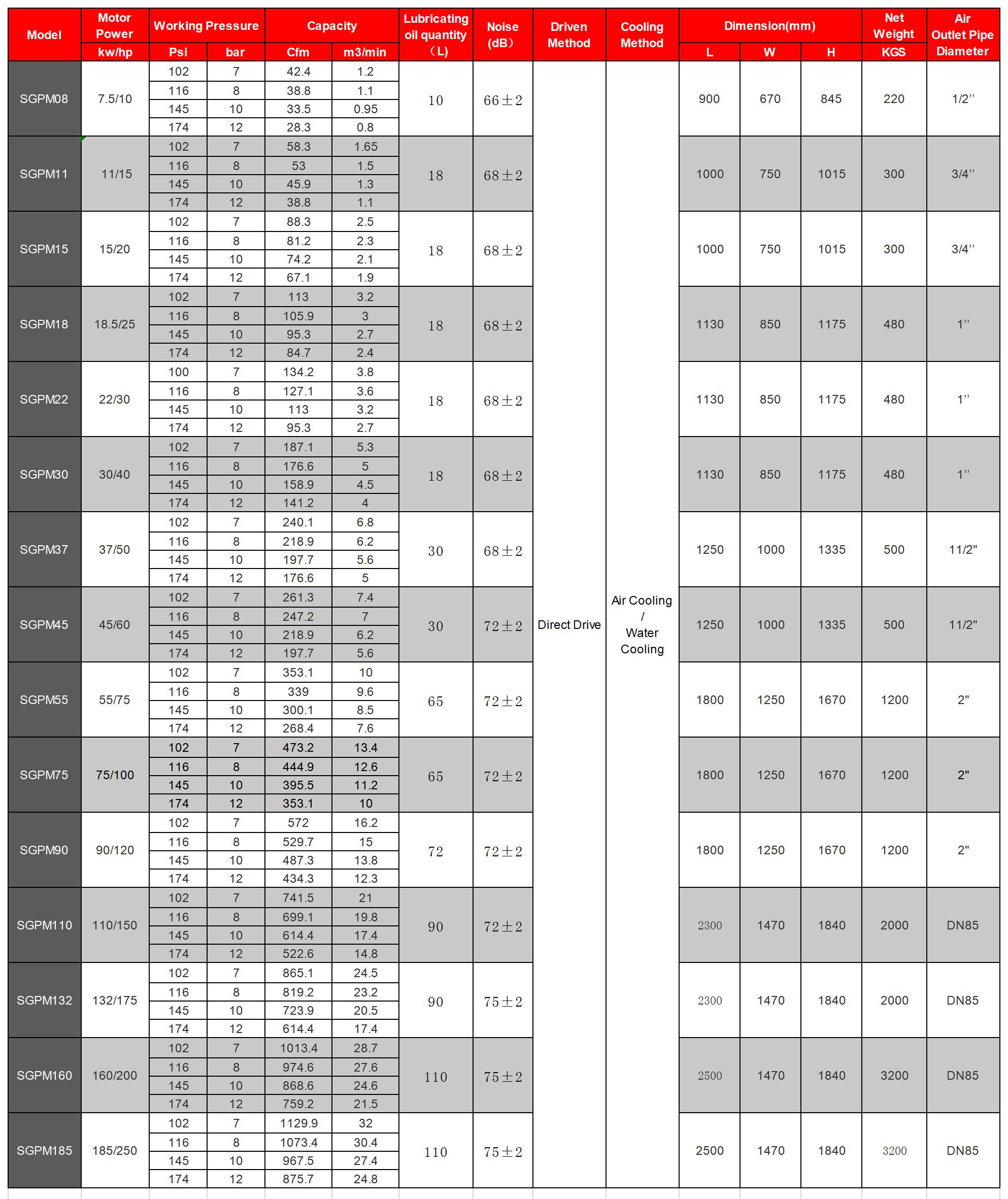

Low vibration and noise levels: Thanks to precise industrial and balanced design, our compressors operate with minimal vibration and noise. This makes it suitable for use in environments where noise pollution is a concern.

Compact and sturdy structure: The air compressor is designed to be compact, easy to install, and requires less space, making it an ideal choice for facilities with limited space. The sturdy structure ensures durability and lifespan, even under harsh working conditions.

Application universality: Aivyter air compressors are suitable for a wide range of industries including manufacturing, construction, and mining, with a wide range of applications that can meet specific needs.

The PM Frequency Conversion Screw Compressor saves 10%-15% more energy than a variable speed screw compressor, while it saves 30%-40% more energy than a standard screw compressor.

This PM motor is crafted with high performance permanent magnet material, providing an impressive 15 year lifespan without losing magnetism at temperatures as high as 120℃. Without the need for motor bearings, a permanent magnet rotor is directly mounted on the stretch out shaft of the male rotor for a trouble-free operation. When compared to other variable speed motors it boasts improved energy efficiency levels and even maintains a high level of efficiency when running at low speeds.

Our compressor features a unique design that integrates a permanent magnet motor and a screw compressor, resulting in a compact and efficient unit. It utilizes an advanced control system that monitors and adjusts the motor speed and the system pressure to optimize performance and energy efficiency. Additionally, our compressor is equipped with an intelligent fault diagnosis system that detects and alerts any potential problems in real-time.

Before sale

Professional online salesman can solve compressor system problems for you.

Provide free air compressor energy saving solutions to help you save operating costs.

After sale

Online professional after-sales service Online professional after-sales service until the problem is solved.

After commissioning, the warranty is 1 year or the delivery date is 16 months, which depends on the first warranty of the whole machine (except repair consumables).

The number of spare parts is sufficient to ensure good after-sales service.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara