11kw 15hp Permanent Magnet Frequency Conversion Screw Air Compressor

The Aivyter PM Series lubricated screw compressors are designed to provide the highest levels of quality, reliability, performance and efficiency. The PM Series is powered by high-efficiency electric motors, ensuring low CO2 emissions without sacrificing power or performance. Featuring a specially designed screw airend, the PM Series utilizes the latest CNC rotor grinding and permanent magnet synchronous motors to ensure unparalleled reliability and performance while reducing operating costs.

Equipped with IE5 and IE3 electric permanent magnet motors, offering a pressure range of 7 to 12bar. A large surface aftercooler is used to maintain low operating and discharge temperatures, while a high-performance two-stage filtration system delivers the highest levels of air purity with oil residues below 3 ppm.

Product Features:

1. The air pressure of permanent magnet variable frequency air compressor is stable

Because the frequency conversion screw air compressor uses the stepless speed regulation characteristics of the frequency converter, it can start smoothly through the controller or the PID regulator inside the frequency converter; it can quickly adjust the response to the occasions where the air consumption fluctuates greatly. Compared with the upper and lower limit switch control of power frequency operation, the air pressure stability is improved exponentially.

Second, the permanent magnet variable frequency air compressor starts without impact

Since the frequency converter itself contains the function of a soft starter, the starting current is larger than 1.2 times the rated current. Compared with the power frequency starting at more than 6 times the rated current, the starting impact is small. This impact is not only on the power grid, but also on the entire mechanical system, which is also greatly reduced.

3. Variable flow control of permanent magnet variable frequency air compressor

The air compressor driven by industrial frequency can only work at one displacement, while the frequency conversion air compressor can work at a relatively wide range of displacement. The frequency converter adjusts the motor speed in real time according to the actual air consumption to control the air displacement. When the air consumption is low, the air compressor can be automatically hibernated, which greatly reduces the energy loss. The optimized control strategy can further improve the energy-saving effect.

Fourth, the voltage adaptability of the AC power supply of the permanent magnet variable frequency screw air compressor is better

Due to the over-modulation technology adopted by the frequency converter, it can still output enough torque to drive the motor when the AC power supply voltage is slightly lower; when the voltage is higher, it will not cause the output voltage to the motor to be higher. For the occasion of self-generation, the variable frequency drive can show its advantages. According to the characteristics of the motor VF (variable frequency air compressors work below the rated voltage in an energy-saving state), the effect is obvious for sites with low grid voltage.

5. Permanent magnet variable frequency energy-saving air compressor has low noise

Most of the working conditions of the frequency conversion system are lower than the rated speed, the main machine's mechanical noise and wear are reduced, and the maintenance and service life are prolonged. If the fan is also driven by frequency conversion, the noise of the air compressor can be significantly reduced.

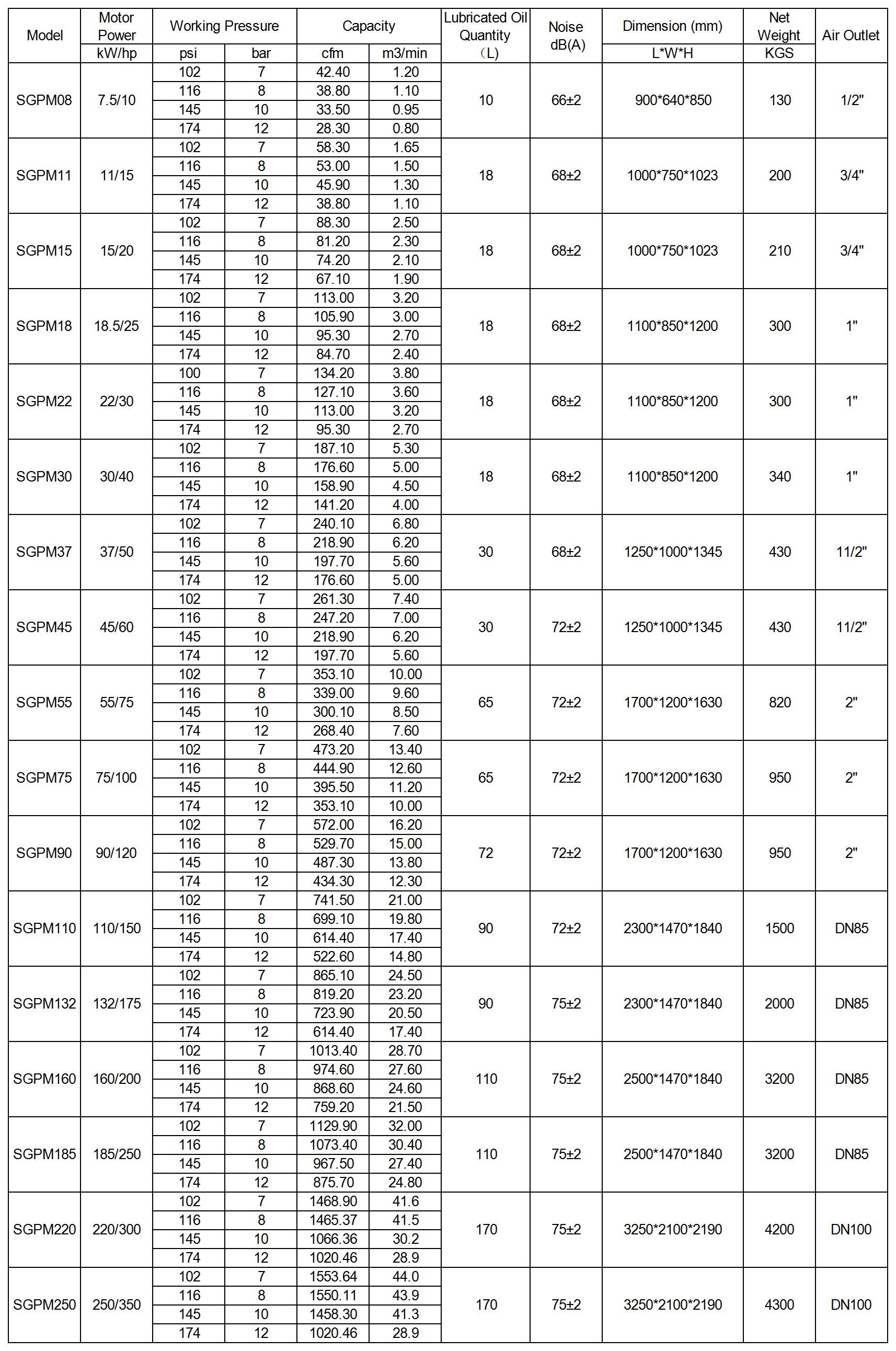

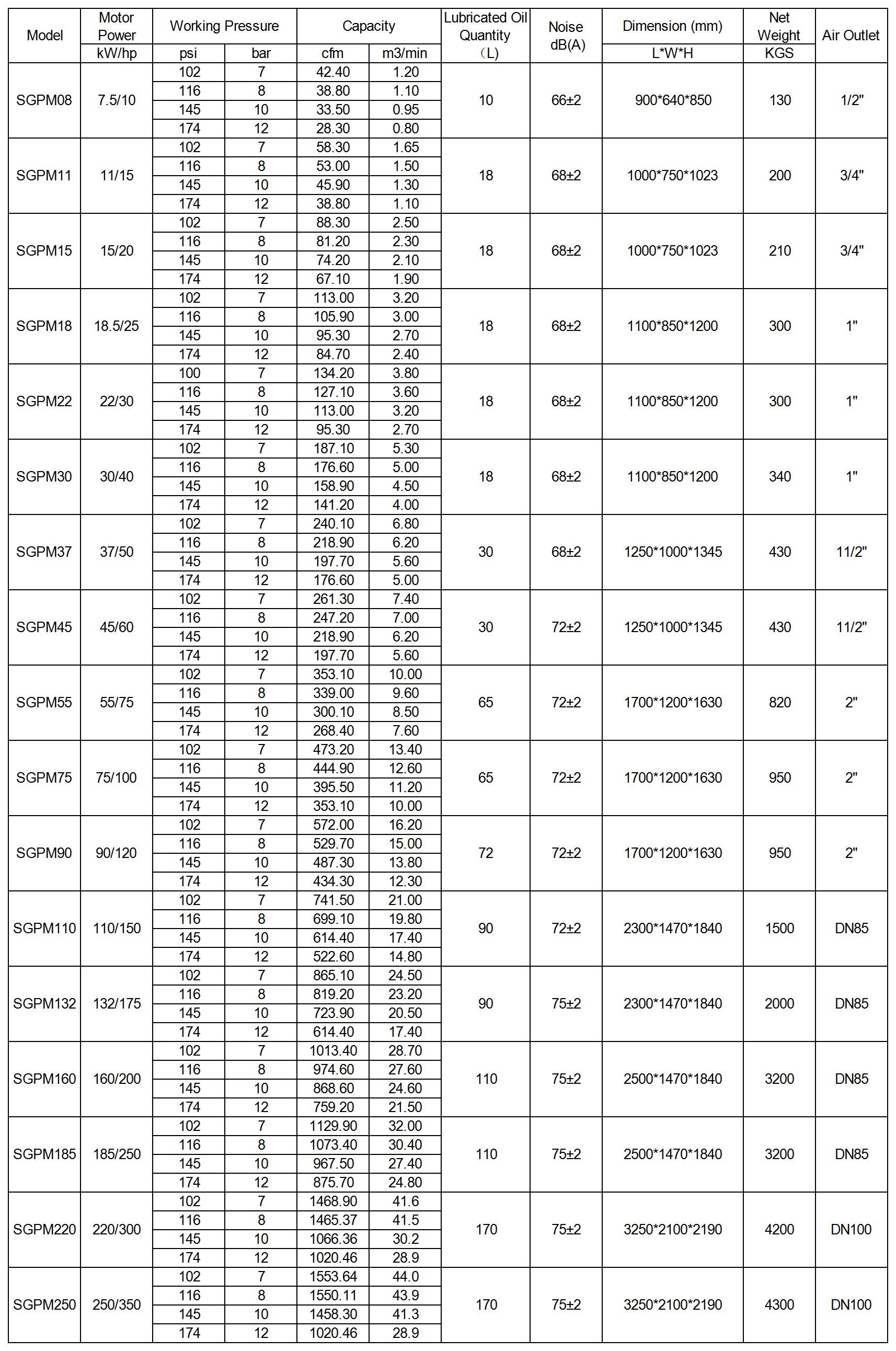

Product Parameter:

| Model | SGPM 11 | Discharge Pressure(Mpa) | 0.7 / 0.8 /1.0 /1.2 |

| Air Delivery(m³/min) | 1.65/1.5/1.3/1.1 | Power(kW) | 11 |

| Lubricant(L) | 18 | Drive Method | Variable frequency starting |

| Cooling | Air | Discharge Temperature(℃) | ≤Ambient temperature±15℃ |

| Electricity(V/Hz) | 380V/50Hz(customizable) | Weight(kg) | 360 |

| Dimension(mm) | 1080*750*1020 | Air Outlet Pipe Diameter(inch/mm) | G3/4'' |

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara