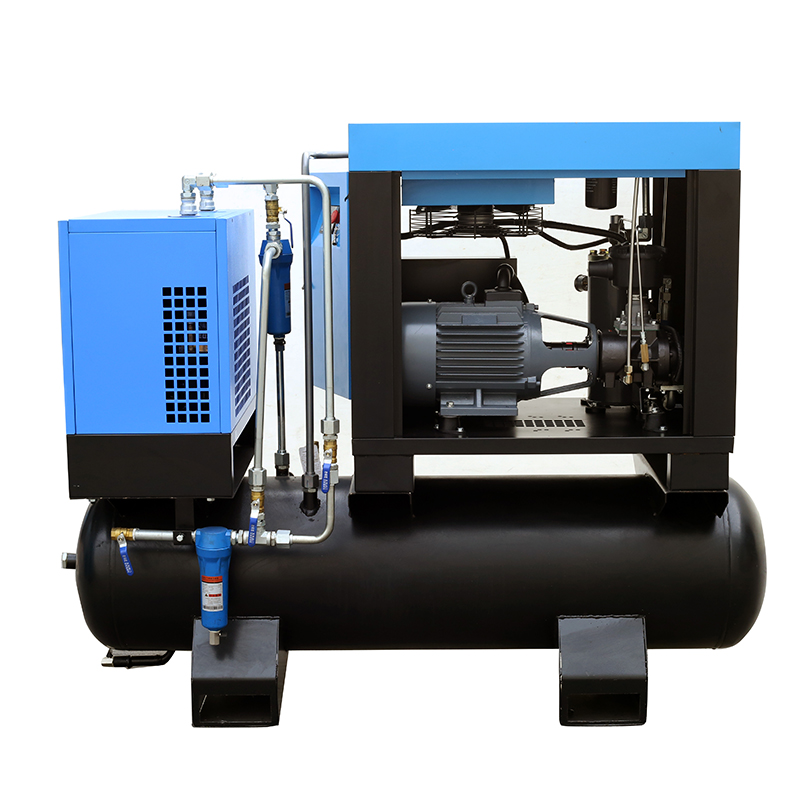

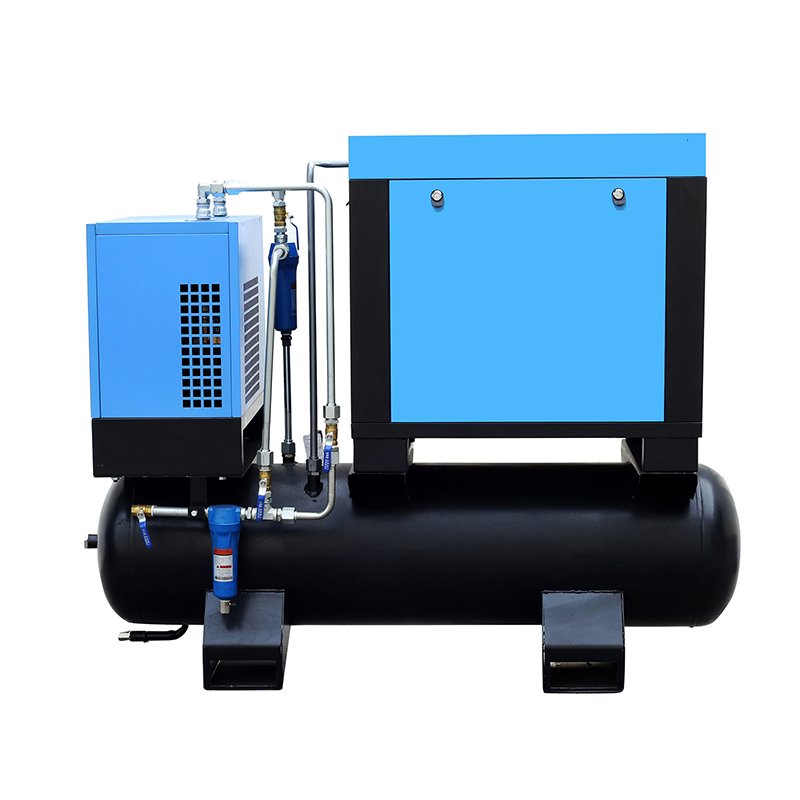

15kw 20hp Industrial Screw Air Compressor With Dryer And Air Tank

Integrated Type Screw Air Compressor

The integrated screw air compressor integrates screw air compressors, freeze dryers, precision filters, air storage tanks and other components. The user is convenient to install, simple to use, and flexible to move. After the air is integrated with the system, the air quality is significantly optimized, which can meet the process needs of various enterprises.

This integrated screw air compressor features a 350L tank, 20hp three-phase motor, and is connected directly to the screw compression airend so there are no belts to worry about.

Designed for continuous operation

The high-efficiency motor and screw compressor unit is designed for continuous operation, with long service intervals and low maintenance costs, and features an integrated air dryer to remove moisture that enters the tank.

Easy to maintain

Comprehensive maintenance is possible via easily removable side panels on the fully enclosed, sound-deadening canopy.

digital control panel

Digital control panel monitors pressure, voltage, current, hours

Forklift transport port

Equipped with forklift transport holes to facilitate transportation and installation.

A 3/4 inch outlet fitting and CE certified drain tap for pressures up to 8 10 15 16 bar etc.

Application industry

Ideal for spray shops, tire repair shops, large workshops, small factories, etc.

1. Integrated design products

(1) Fewer parts and connectors, reducing the possibility of unit failure and leakage;

(2) The integrated piping system greatly reduces pressure loss;

(3) Directly eliminate dry compressed air to fully guarantee the air quality of the user terminal;

(4) Save installation space,Integrate the compressor, dryer and filter into an energy-saving, optimized system;

2. High performance cold dryer

Adopting high-performance refrigeration and drying machines, R134A, R410A environmentally friendly refrigerants (commonly known as non-fluorine refrigerants) have beautiful appearance, compact structure and high-cooling capacity configuration scheme of rotary refrigeration compressors to ensure reliable operation under high temperature conditions.

Product Specifications:

| Model | Motor Power | Working Pressure | Capacity | Air tank (L) | Air Outlet | Net Weight | Dimension (mm) | Start Method | Noise

dB(A) |

| kW/hp | psi | bar | cfm | m3/min | KGS | L*W*H |

| SGAT08 | 7.5/10 | 116 | 8 | 38.84 | 1.1 | 350 | G1/2'' | 350 | 1850*700*1460 | Y-△ | 66±2 |

| 145 | 10 | 32.00 | 0.90 |

| SGAT11 | 11/15 | 116 | 8 | 52.97 | 1.5 | 350 | G3/4’’ | 450 | 1850*750*1640 | 68±2 |

| 145 | 10 | 45.90 | 1.3 |

| 174 | 12 | 38.84 | 1.1 |

| SGAT15 | 15/20 | 116 | 8 | 81.00 | 2.3 | 350 | G3/4" | 450 | 1850*750*1640 | 68±2 |

| 145 | 10 | 74.00 | 2.1 |

| 174 | 12 | 67.10 | 1.9 |

| SGAT22 | 22/30 | 116 | 8 | 127.10 | 3.6 | 350 | G1" | 660 | 2050*850*1780 | 68±2 |

| 145 | 10 | 113.00 | 3.2 |

| 174 | 12 | 95.30 | 2.7 |

| SGAT08PM | 7.5/10 | 116 | 8 | 39.00 | 1.1 | 350 | G1/2'' | 350 | 1850*700*1460 | Frequency Conversion | 66±2 |

| 145 | 10 | 32.00 | 0.90 |

| SGAT11PM | 11/15 | 116 | 8 | 52.97 | 1.5 | 350 | G3/4’’ | 450 | 1850*750*1640 | 68±2 |

| 145 | 10 | 45.90 | 1.3 |

| 174 | 12 | 38.84 | 1.1 |

| SGAT15PM | 15/20 | 116 | 8 | 81.00 | 2.3 | 350 | G3/4" | 450 | 1850*750*1640 | 68±2 |

| 145 | 10 | 74.00 | 2.1 |

| 174 | 12 | 67.10 | 1.9 |

| SGAT22PM | 22/30 | 116 | 8 | 127.10 | 3.6 | 350 | G1" | 660 | 2050*850*1780 | 68±2 |

| 145 | 10 | 113.00 | 3.2 |

| 174 | 12 | 95.30 | 2.7 |

After Sales Service

Before sale

Professional online salesman can solve compressor system problems for you.

Provide free air compressor energy saving solutions to help you save operating costs.

After sale

Online professional after-sales service Online professional after-sales service until the problem is solved.

After commissioning, the warranty is 1 year or the delivery date is 16 months, which depends on the first warranty of the whole machine (except repair consumables).

The number of spare parts is sufficient to ensure good after-sales service.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara