Product Advantage

18.5kW 25Hp 240V Direct Drive Industrial Screw Air Compressor

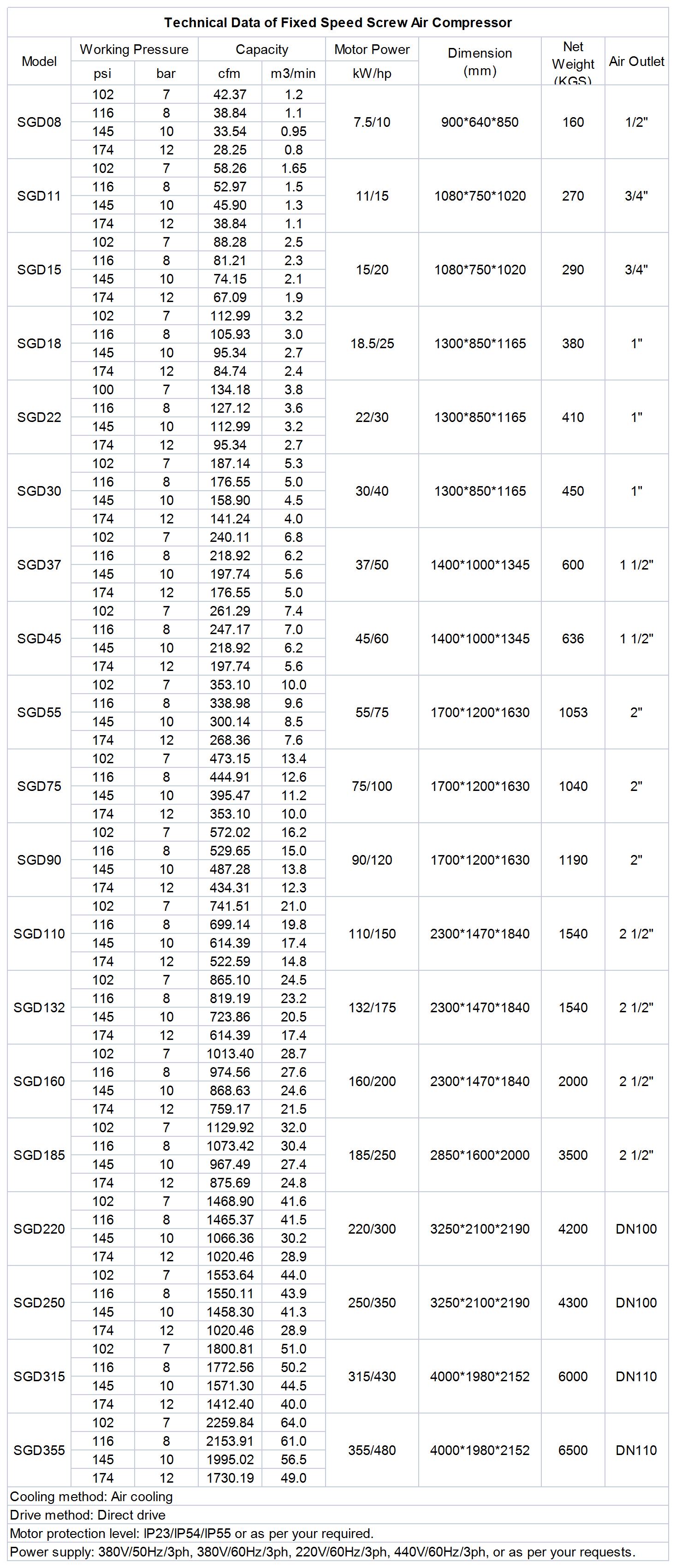

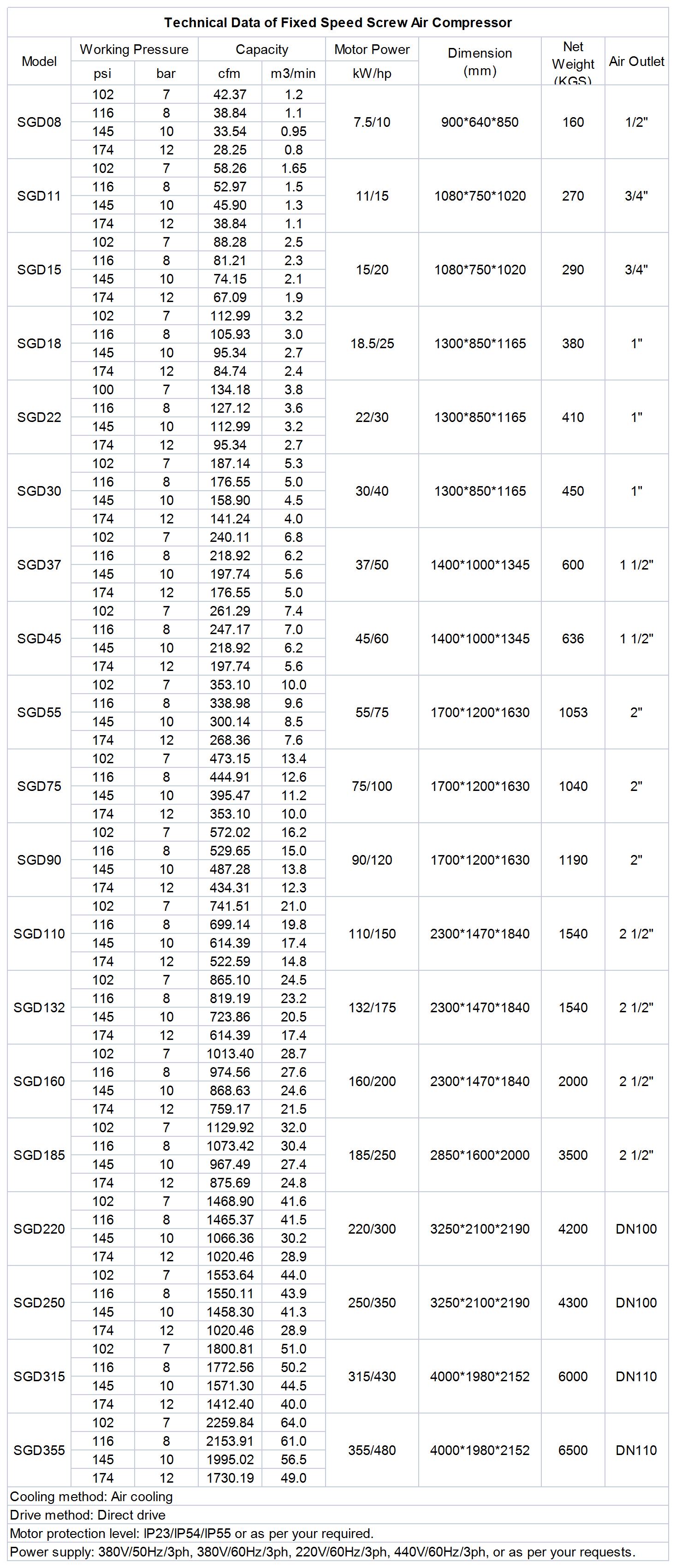

18.5kw 25hp fixed speed (non-VSD) compressor delivers 106Cfm at 116 psi and 85 cubic feet per minute at 145 pounds per square inch. When using an 18.5kw screw air compressor, oil is needed to keep the compression process going smoothly. To maximize profitability and design your installation to suit you, these compressors can be placed with a variety of air equipment and accessories. They are ideal for applications with constant compressed air demand. The engine on the machine will always run at the same speed 24 hours a day unless turned off.

Unparalleled power and efficiency:

The aivyter 18.5kW, 25 horsepower (Hp) direct drive industrial screw air compressor is designed to provide excellent performance and reliability. With its powerful and efficient motor, it can ensure that your industrial operation receives a continuous and stable supply of compressed air pressure.

Direct Drive technology:

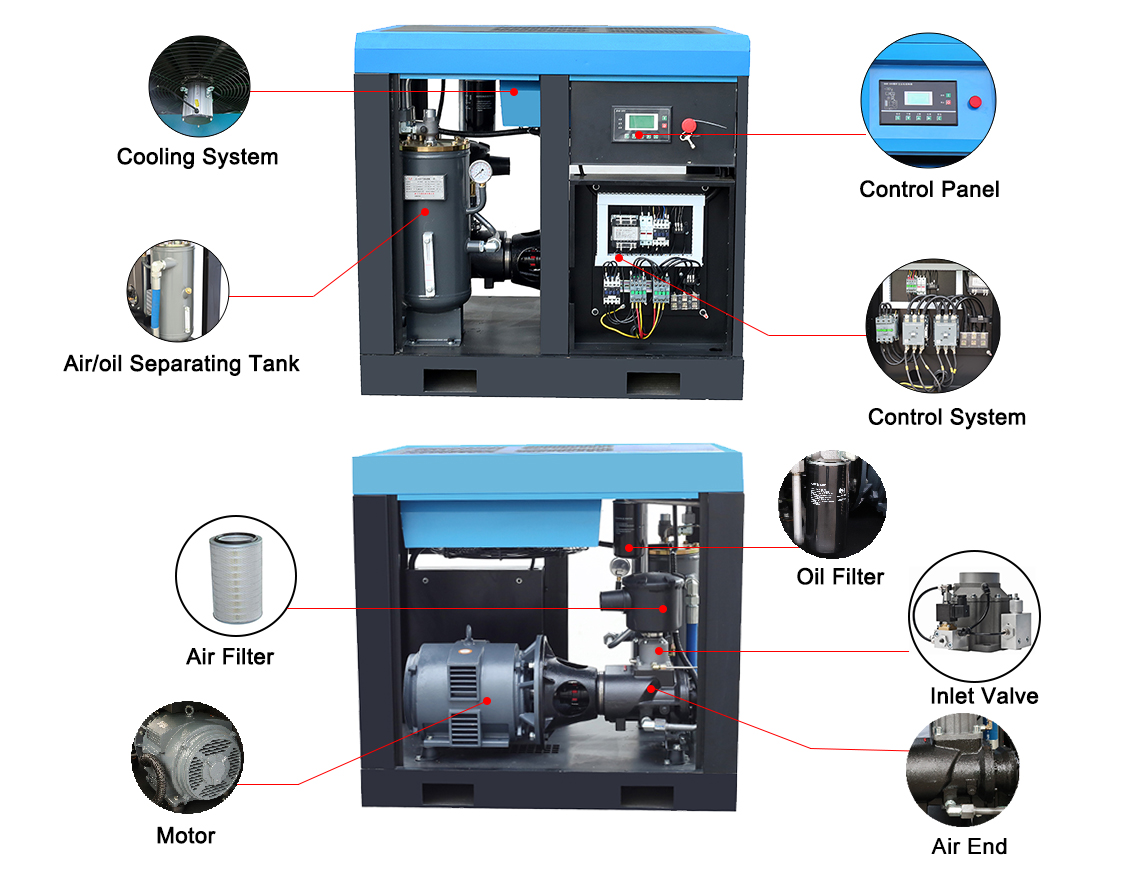

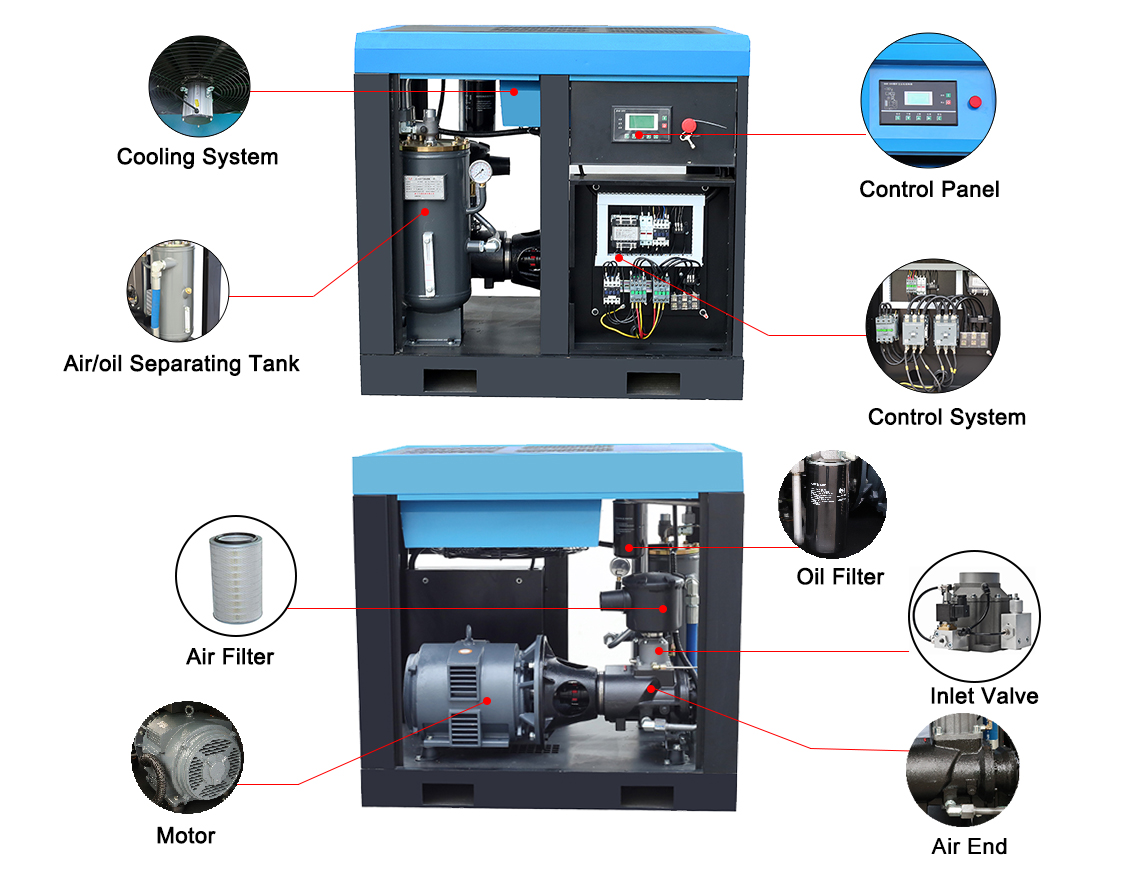

The aivyter air compressor adopts a direct drive system without the need for belt connection, reducing energy loss, improving overall efficiency, and saving electricity costs. By bypassing traditional transmission systems, our compressors require less maintenance and fewer consumables, saving you time and resources. The direct drive mechanism is more durable than belt connections, ensuring a longer service life and reducing replacement frequency. This compressor is made of heavy-duty materials and can withstand harsh industrial environments. Specially designed for 24-hour continuous operation, providing a reliable source of compressed air for your demanding industrial processes. Innovative screw mechanisms help to better dissipate heat and maintain ideal operating temperatures. Despite its powerful performance, our compressor has a compact structure and is easy to integrate into existing workspaces.

Intelligent Control System: Advanced control systems can monitor and adjust operations to achieve maximum energy efficiency.

Safety functions: equipped with multiple safety functions to prevent overload and system failures.

User friendly interface: The control panel is intuitive, making it easy to operate and monitor the status of the compressor. Customizable remote detection operating system, directly connected to the mobile app, without the need for manual monitoring of the air compressor room.

Suitable for a wide range of industries including manufacturing, construction, and automotive maintenance. Very suitable for providing power for pneumatic tools, factory workshops, and other applications that require compressed air.

Product Parameters

What should be paid attention to in the daily use of screw air compressors?

The correct use of screw air compressors plays a key role in the operation of the unit and the safety of personnel. If you do not pay attention to the operation, it is easy to cause equipment failure. With the continuous advancement of technology, many screw air compressors have now achieved equipment monitoring without going to the machine room. Although this method is convenient and quick, manual inspection cannot be ignored. So what should be paid attention to in the daily use of screw air compressors?

What should be paid attention to in the daily use of screw air compressors?

1. Check the oil level in the oil and gas separator before starting the machine, and slightly open the oil drain valve below the oil and gas separator to remove the possible condensed water in it. After confirming that there is no condensed water, tighten the valve and open the air supply port valve of the air compressor.

2. After setting the operating parameters, press the start button.

3. During the operation of the screw air compressor, it is necessary to observe whether there is abnormal vibration, noise, leakage of gas and oil, and whether the lubricating oil is sufficient.

4. Close the cover door to control the noise of the unit and ensure the normal flow of cooling air.

5. Slowly close the air supply shut-off valve to check whether the unit is unloaded as set.

6. Check whether the parameters such as pressure, exhaust temperature, and the indicated value of electrical instruments are normal.

7. For the water-cooled unit, it is necessary to check the inlet water pressure, and adjust the waterway ball valve to keep the exhaust temperature of the unit within the normal range.

8. Please carefully observe the operation of the compressor in the first hour of operation, and observe it every 6 hours after that. If there is any abnormality, it should be stopped in time for maintenance.

9. After the initial operation, stop the machine according to the shutdown procedure, check whether the oil tank needs to be filled with lubricating oil; check whether the joints are loose. The above is what you need to pay attention to in the daily use of screw air compressors. Have you learned it?

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara