Product highlights:

Overall upgrade of core components:

Airend and motor adopt direct connection: improve air production efficiency and save energy

Transform the engagement and sealing of the rotor: improve volumetric efficiency and reduce compressor noise.

Optimize the distance between the iron core and the rotor: improve the utilization rate of the rotor; Extend the service life of bearings.

The upgrade characteristics and overall structure of PLC controllers.

English PLC controller interface - automatic control, automatic protection, automatic alarm, remote control, and simultaneous operation of multiple compressors.

Integrated temperature control: Maintain oil temperature, reduce pipeline interfaces, and ensure stable machine operation.

Closed cooling system: a new type of cooling fan that matches the new fan.

Our aivyter high-efficiency rotary closed screw air compressor adopts advanced Direct Drive screw technology to ensure efficient compression of air. Precision designed rotors can minimize energy loss, maximize air output, thereby increasing productivity and reducing operating costs.

The design of this compressor takes into account energy efficiency and reduces motor energy loss. The integrated variable speed drive (VSD) system allows the compressor to adjust its speed according to air demand, significantly reducing energy consumption during low demand periods. This intelligent design not only saves energy, but also extends the service life of the compressor.

Ensuring clean and high-quality compressed air is crucial for many industrial applications. Our efficient rotary closed screw air compressor is equipped with advanced filtration system and excellent post-treatment system. These components can effectively remove moisture, oil, and pollutants, providing clean and dry compressed air for your process.

The aivyter compressor has noise reduction capabilities, including sound insulation materials and advanced vibration reduction technology. The result is low-noise operation, minimizing interference and improving workplace comfort. It is also equipped with an intelligent control system, which can easily monitor and control various parameters. A user-friendly interface provides real-time data on pressure, temperature, and power consumption, allowing you to optimize compressor performance and ensure efficient operation.

This compressor can withstand harsh industrial environments and has a sturdy and durable structure. High quality materials and components ensure long-lasting performance and minimum maintenance requirements. After appropriate maintenance and regular repairs, this compressor will provide reliable compressed air in the next decade.

We are committed to providing excellent after-sales support to our customers. Our expert team can assist with installation, maintenance, and troubleshooting. We provide warranty coverage and ready-made spare parts supply to ensure uninterrupted operation and customer peace of mind.

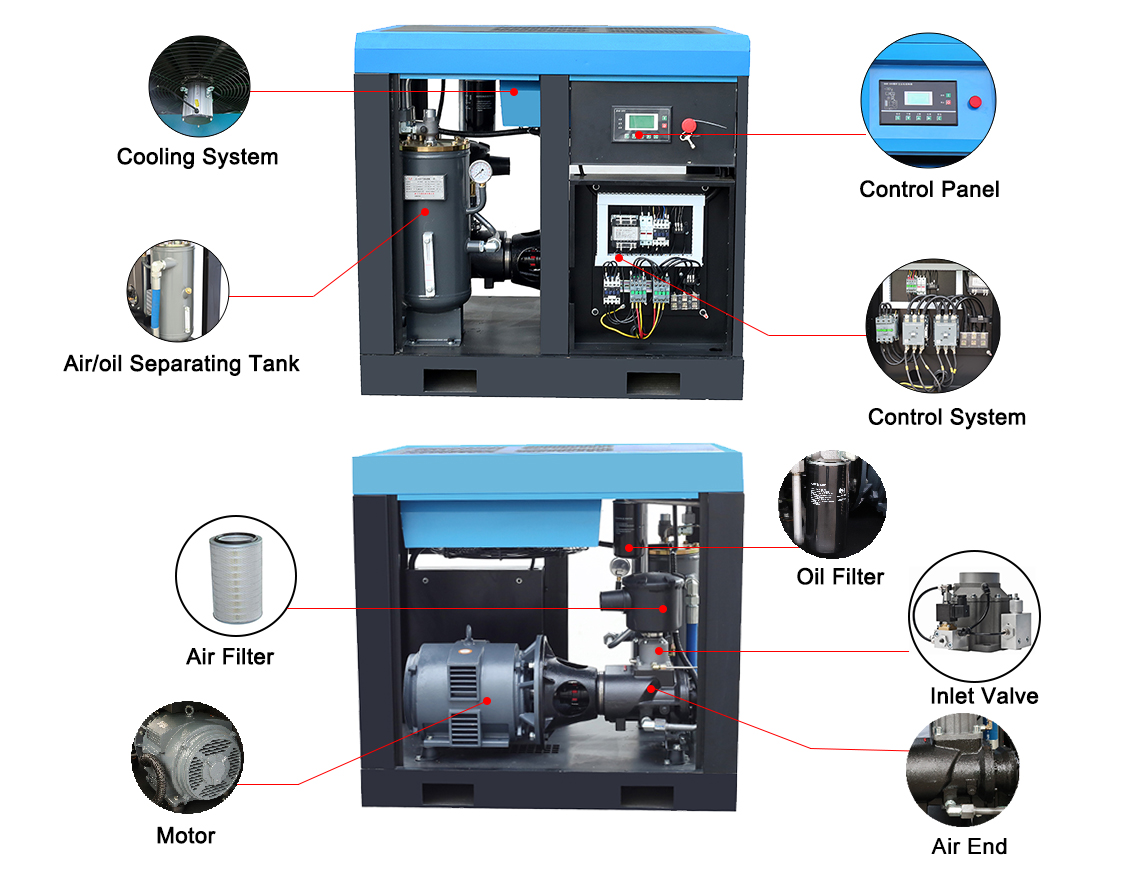

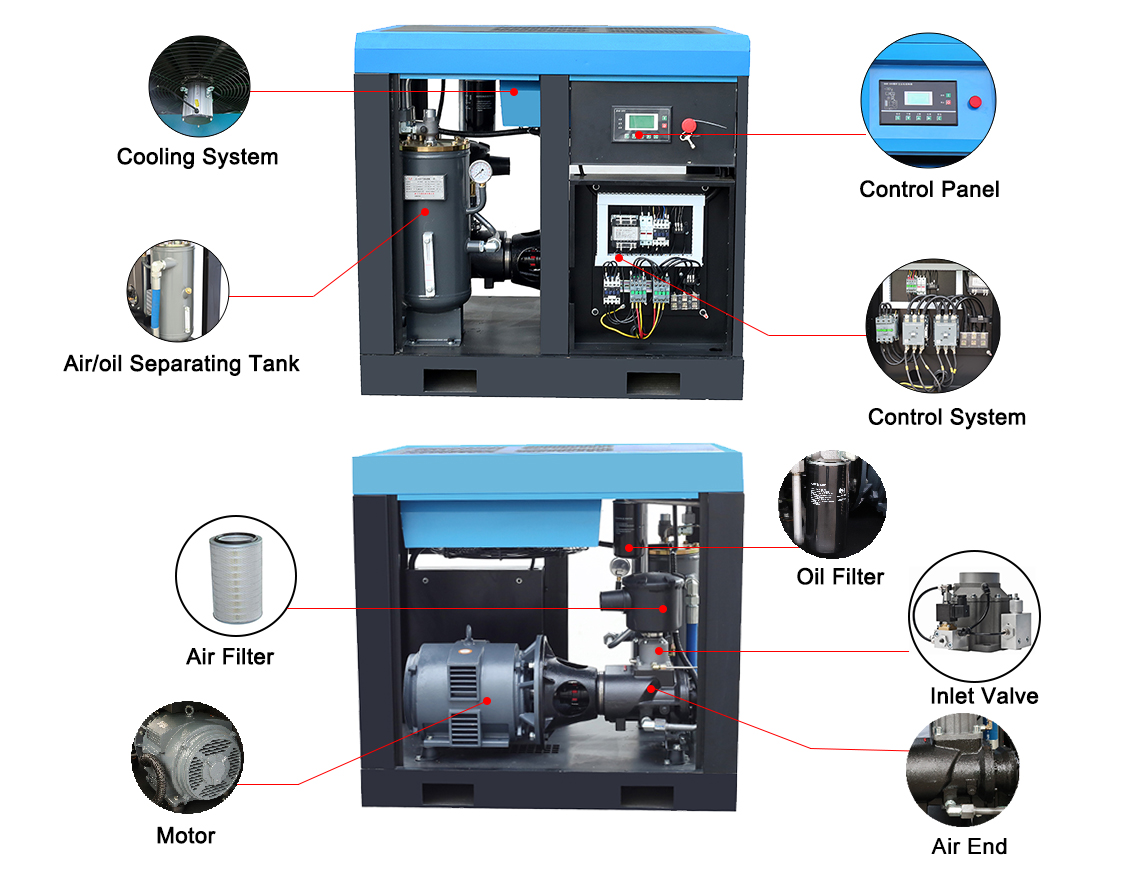

Air end

Air end is equipped with lasted rotors with bigger diameter and low rotate speed, high –quality SKF over loading bearing, the powerful heart ensures good performance of the whole air compressor.

Air inlet valve

World-renowned brands, air input can be automatically adjusted from 0% to 100%, reducing operation cost.

Air filter

With low flow resistance design and large dust holding capacity to make sure the high purity of inlet air.

Control panel

Human-based English user interface:Easy to operate and continuously working for 24 hours unattended, English and Russian languages for choosing, accept OEM.

Electric control system

Using famous brands, like SIEMENS, Schneider, greatly improve the service life.

Electric motor

The new Champion 7.5 to 132 kW range has been completely redesigned with changes and optimization innovations in all components of the compressor, including the screw compressor air end, controller and cooling system.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara