Product Introduction

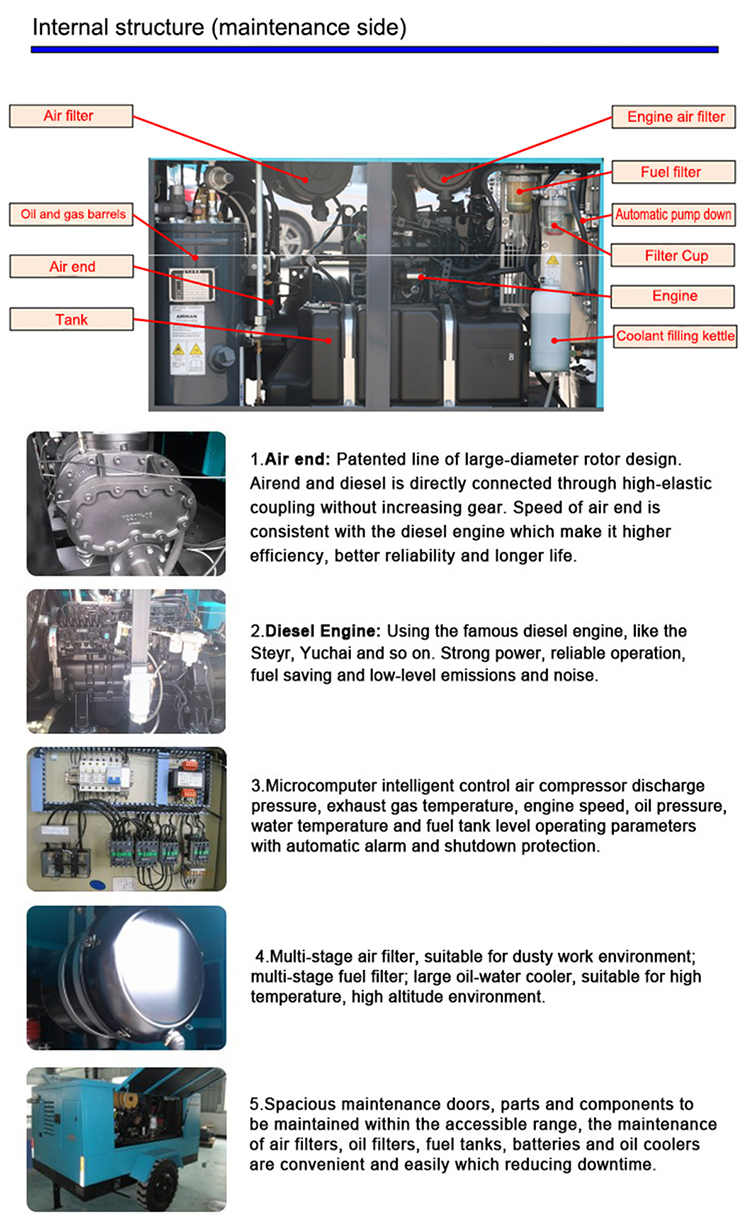

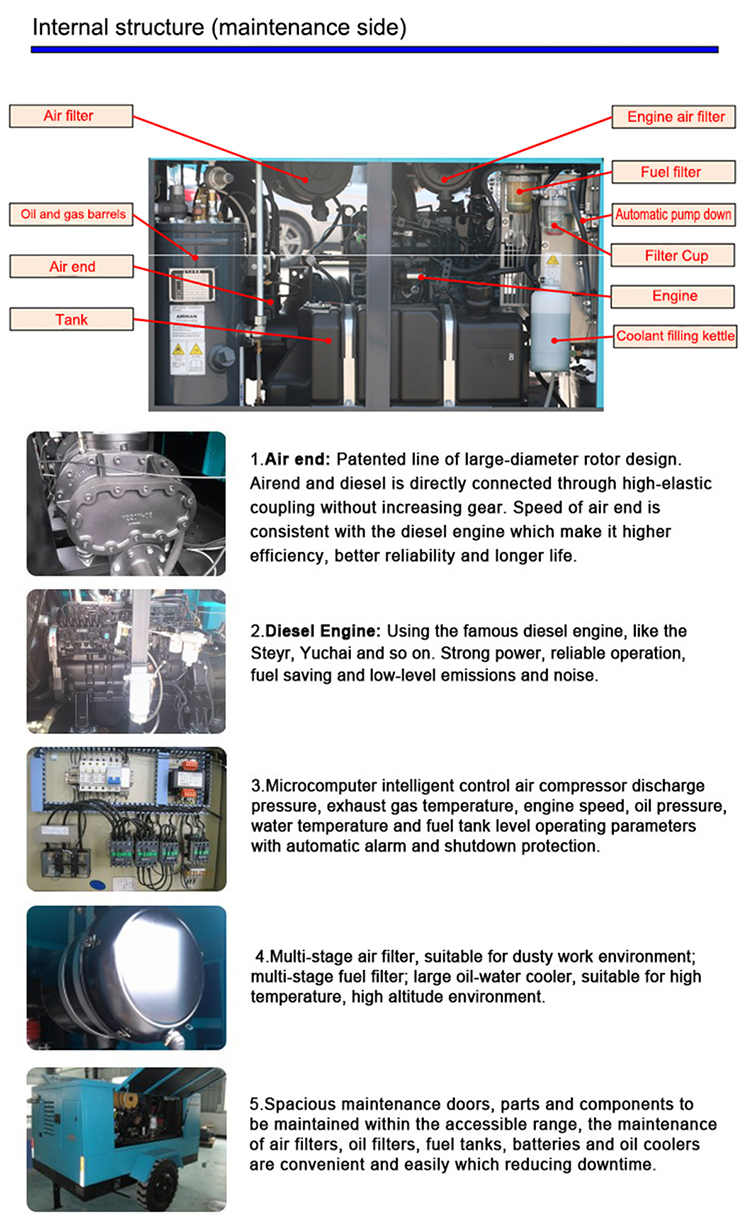

High Pressure Carrier Portable Diesel Screw Air Compressor, This is the ideal solution for sandblasting cleaning applications. This air compressor has undergone precise and efficient design, providing excellent performance even in the most demanding environments.

-Capable of delivering high pressure air up to a specific pressure, such as 25 bar, ensuring effective and efficient sandblasting cleaning.

-This compressor features a sturdy support frame that can be easily transported to various workplaces, providing unparalleled convenience and flexibility.

-The heavy-duty structure ensures long-lasting durability, even in harsh conditions.

-Equipped with brands/models such as Cummins series diesel engines, providing reliable and powerful performance with low fuel consumption.

-The engine meets the latest emission standards and is environmentally friendly.

-Adopting the most advanced screw air compression technology to improve efficiency and reduce energy consumption.

-The screw type air end is designed for continuous operation to ensure maximum productivity.

-Intuitive control panel with easily readable pressure, fuel level, and maintenance alarm instruments and indicators.

-The automatic safety shutdown function can protect the device from damage in the event of low oil pressure, high engine temperature, or other operational issues.

-Very suitable for a wide range of industrial applications, including sandblasting cleaning, sandblasting, construction, mining, etc.

-Capable of operating various pneumatic tools and equipment, making them a source of power for any tool

Product Advantage

1. High quality and reliability: less spare parts, sturdy and durable, long life.

2. Simple, easy to use and maintain: efficient and satisfactory results.

3. High power: stable, high-speed operation, special portable air compressor technology, long life;

4. Suitable for all kinds of difficult environments: the flow is almost not affected by the exhaust pressure, and it maintains high efficiency in a wide speed range.

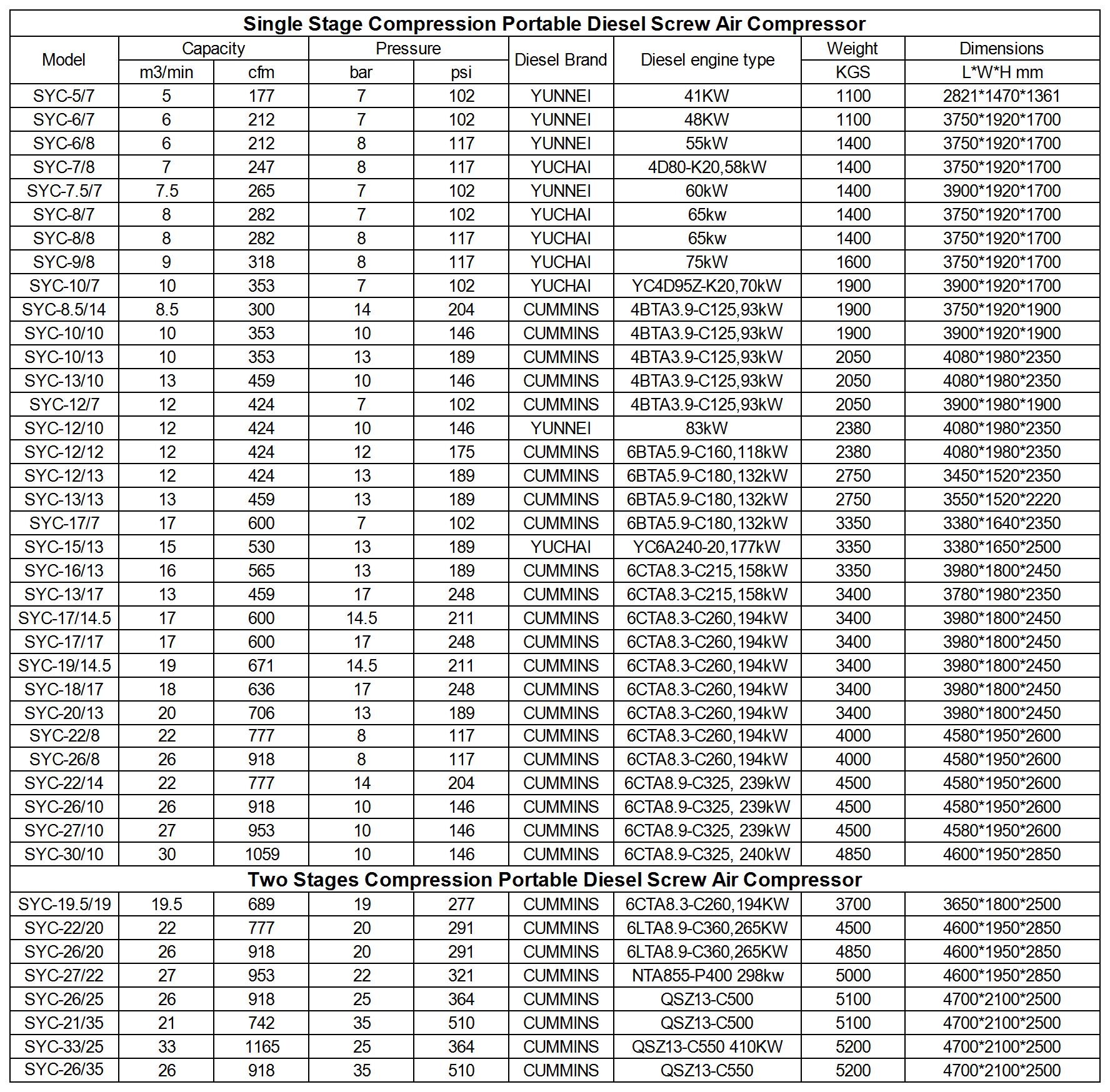

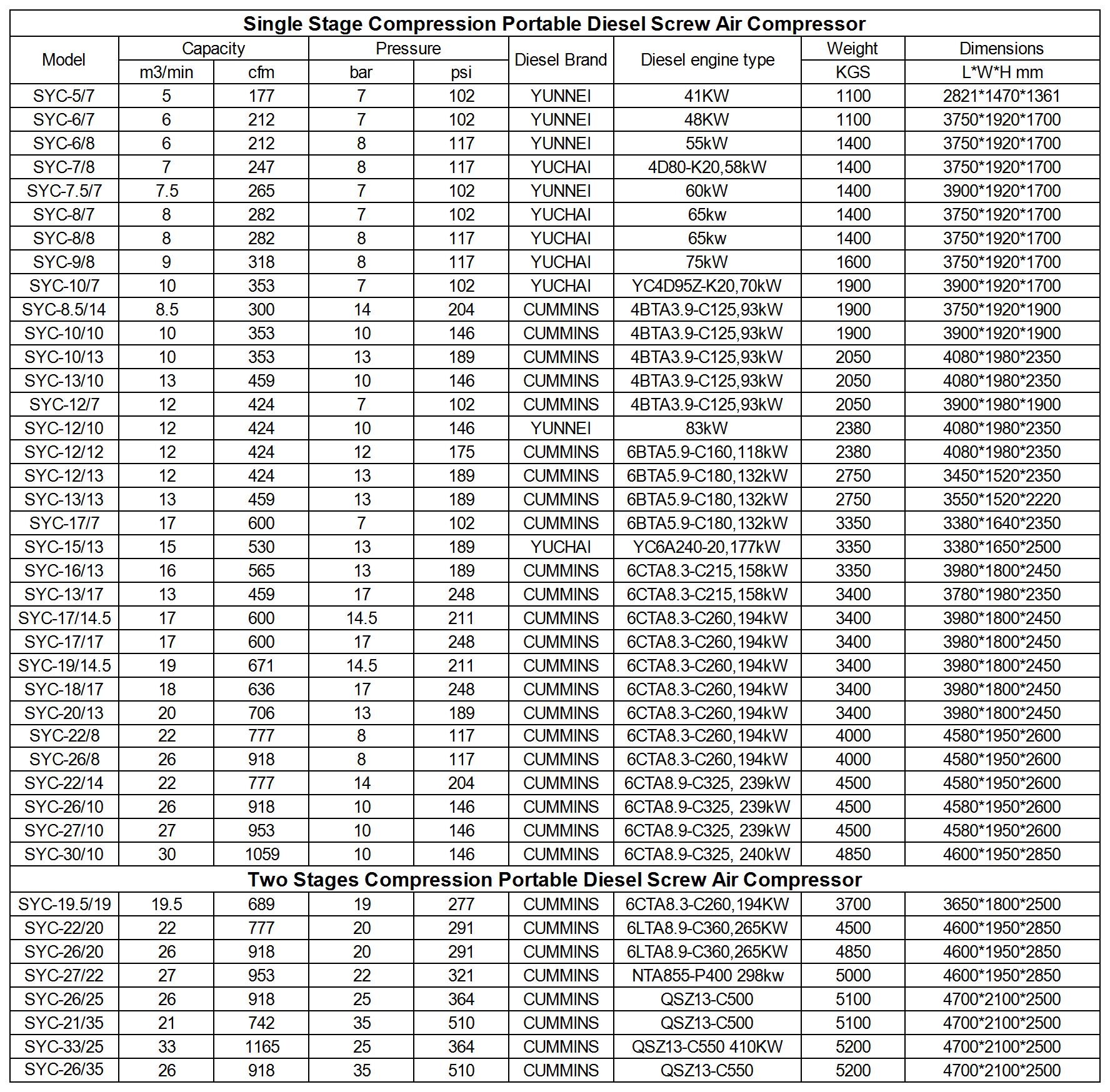

Product Parameters

How the mining industry uses Portable Diesel Screw Air Compressor ?

The mining industry, whether underground or open-pit mining, never rests. Mining is done under harsh conditions, and the mining process runs 24/7-usually in remote areas several miles from the nearest town. The key equipment used to power these processes is the air compressor. Learn more about how air compressors can help keep mining applications running properly below!

Air compressor for mining industry

The entire mining process, from exploration to ore processing, smelting and refining, uses some form of compressed air.

1.drilling. On drilling equipment, compressed air provides power for rotating drill bits, which is similar to jackhammers.

A distributor or pipe located at the bottom of the storage tank introduces compressed air into the storage tank. The entire pipeline is equipped with small holes to ensure uniform air distribution.

2.Smelting and refining. Through the process of melting and heating, the metal is extracted from the ore. This usually occurs in processing plants/smelters close to mining operations and involves air compressors throughout the end-to-end process. However, refining is the process of improving the purity/grade of metals extracted from ore and other raw materials. During the refining process, compressed air helps to oxidize any additional alloy so that no material is wasted.

3.Tools and instruments. Pneumatic tools used in mining require clean, dry air (provided by an air compressor) to work. This ensures the normal operation of drill bits, pneumatic loaders, saws, wrenches, pneumatic loaders and other critical equipment components. The same applies to mining instruments!

4.blasting. Want to break rocks and other materials? Strictly controlling the use of explosives is one way to solve this problem. Compressed air helps this process by providing high-speed airflow to detonate the explosives.

5.ventilation system. Ever wondered how a miner can breathe safely in such a deep place underground? Compressed air can not only provide ventilation for deep mining operations, but also ensure that safe and clean air is available in places such as shelters in emergency situations.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara