Product Introduction

The Hot Sale Cheep Prices 7.5kW 10Hp 12Bar Quiet Screw Air Compressor is a fundamental equipment for industrial modernization. Due to its advantages such as higher efficiency, lower noise, high reliability, stability, and simple maintenance, the 7.5kW screw compressor is more efficient. As the core electromechanical equipment of the pneumatic system and the main body of the air source device, the air compressor converts mechanical energy into gas pressure energy. As a common mechanical device that provides air power, air compressors are applied in various important industries such as food and beverage, pharmaceutical, cigarette, power, heavy industry, chemical fiber, manufacturing, and automotive.

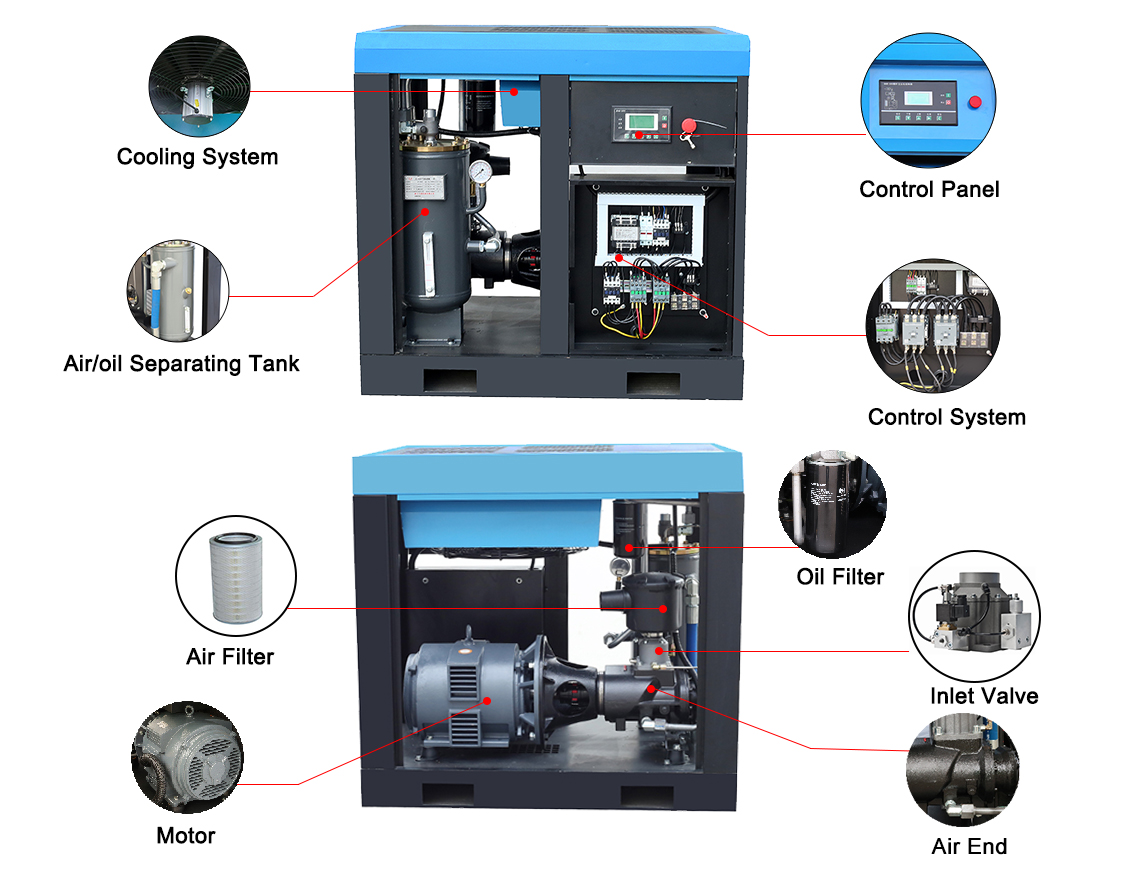

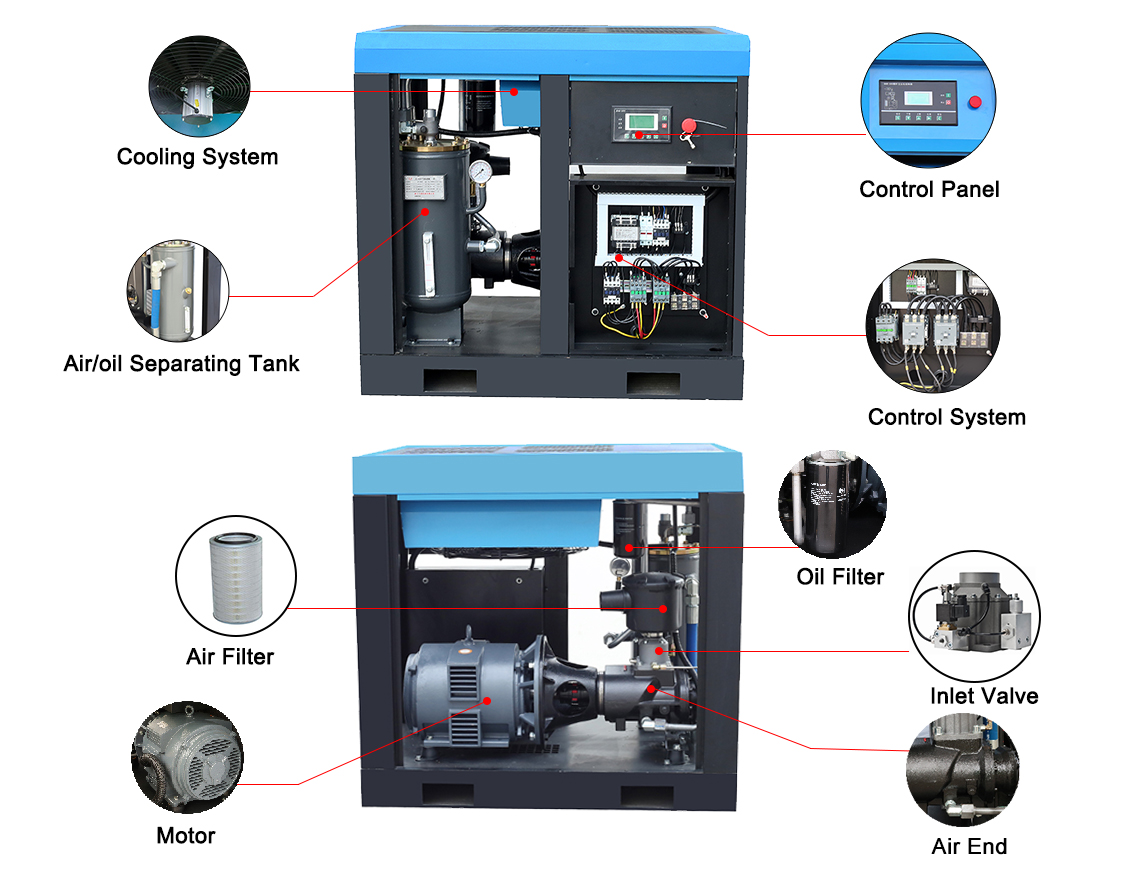

Product Advantage

1. Good machining accuracy and low noise

Aivyter's SGD series screw compressors use advanced technology to reduce the impact, vibration, and noise limits of the machine, effectively extending the lifespan of moving parts. If the noise level of 10HP is only 68 decibels (within 1 meter), it indicates that the moving parts of the compressor have high machining accuracy, low noise, good materials, low impact and vibration, and a long service life of the entire machine. This actually reflects the design and processing level of the machine. Noise is an important indicator of the overall performance of mechanical equipment and a necessary indicator for environmental protection.

2. High configuration of compressor motor and electrical components

In terms of motor configuration, the aivyter screw air compressor adopts protection levels of IP23 and 55, insulation level of IE3, and Siemens distribution system, which is particularly important for hot and humid areas and users with high dust. The poor waterproof and dustproof performance of the motor can greatly increase the risk of motor overload, heating, and even burning. All electrical control parts of our company's compressor, including the Y - (low starting current) starter, are made of Siemens products to ensure accuracy and high reliability in control during multiple starts.

3. Advanced computer control

The intelligent control system has powerful functions, multiple monitoring points, large screen digital continuous display, on-site programming, and other advantages. It also has automatic error detection ability and automatic recording, centralized control, and operation control functions, making management convenient. However, many other brands of compressors either use electronic models with relatively simple functions combined with mechanical instruments, or use single line display single board computers for control, with fewer monitoring points and fewer functions, and only light up when faults occur.

4. Efficient loading and unloading adjustment methods

The full load/no load adjustment method is adopted, which is more efficient and energy-saving compared to the intake throttle method.

5. Non leaking flange connections

The internal pipeline connections of the compressor are all made of flange joints, which not only facilitate disassembly, but more importantly, there will be no oil or gas leakage.

One of the important components is the bearing

The fault free time and lifespan of the host rotor largely depend on the lifespan of the bearings. The bearings are matched by SKF company and have a lifespan 30% longer than ordinary bearings, with a design lifespan of up to 150000 hours.

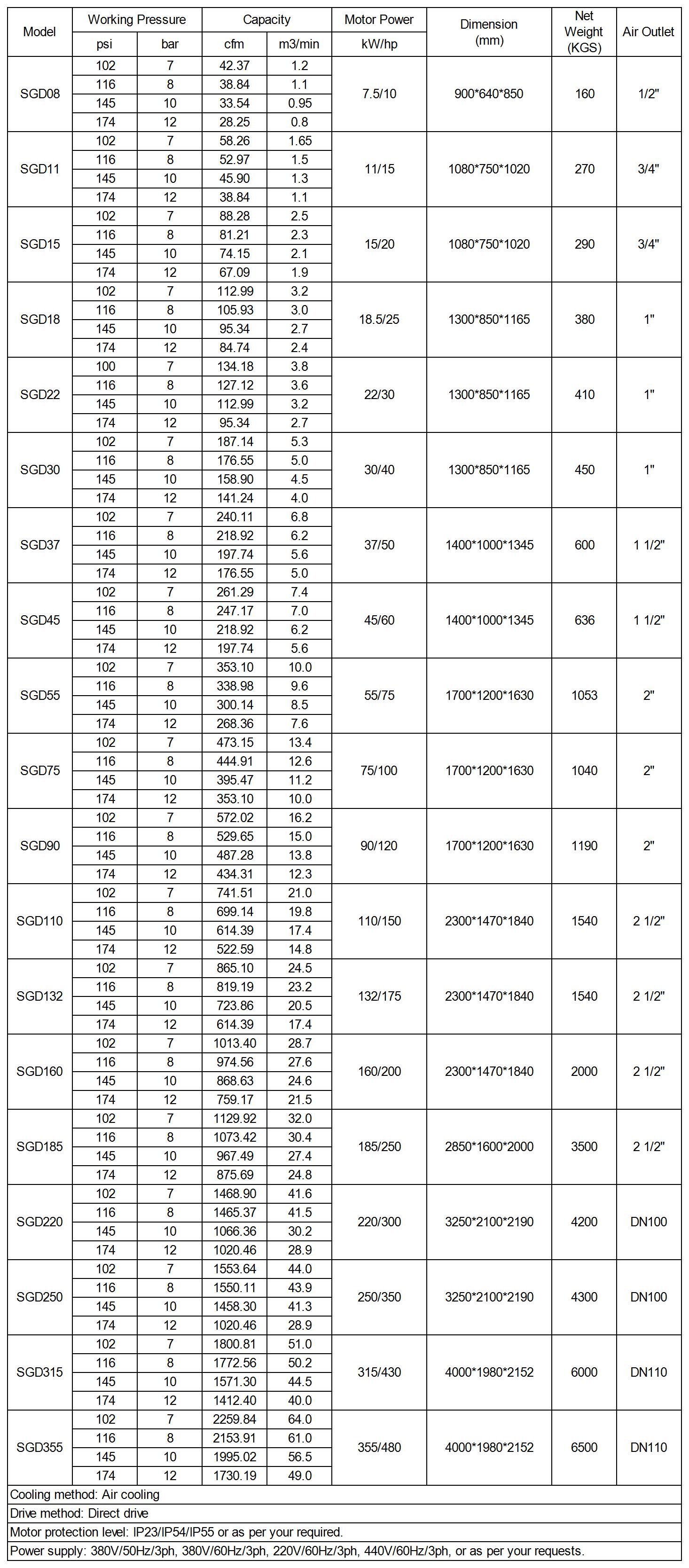

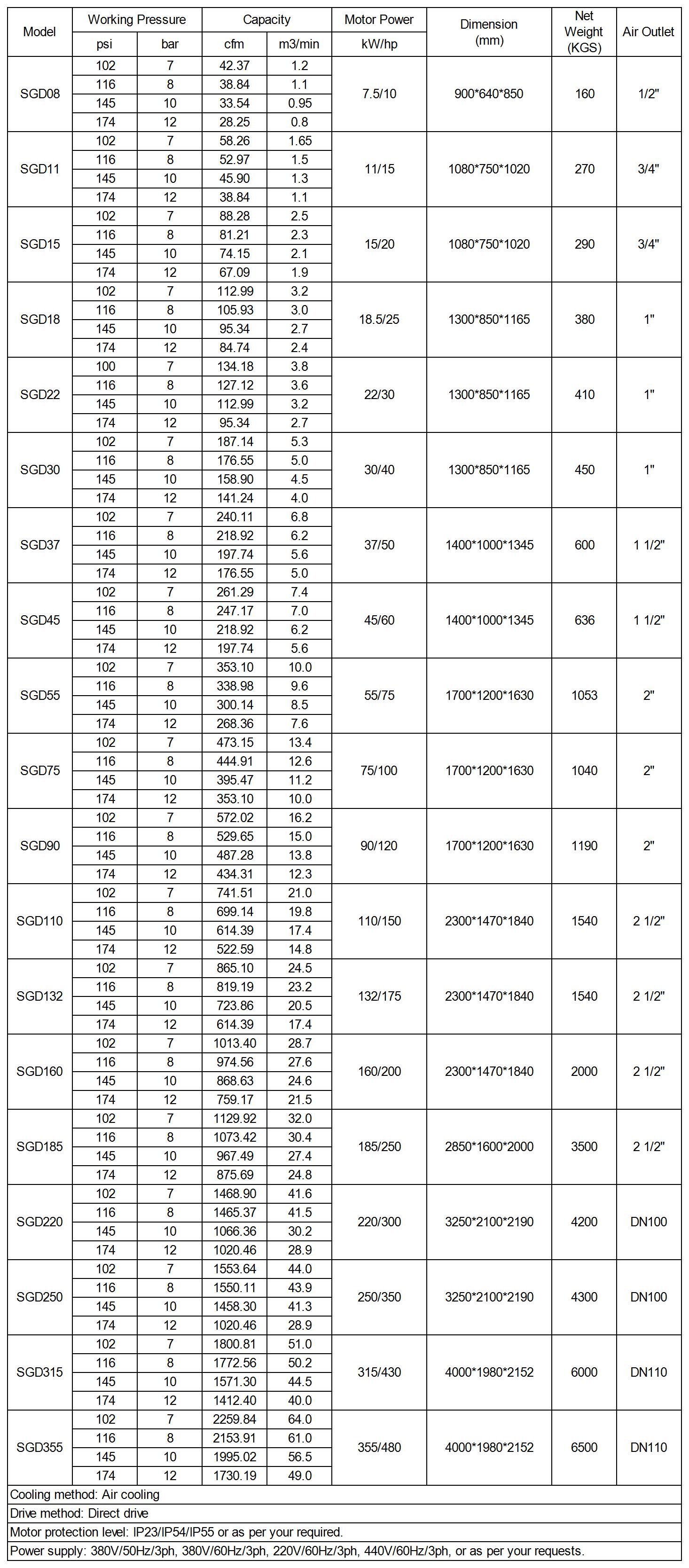

Product Parameters

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara