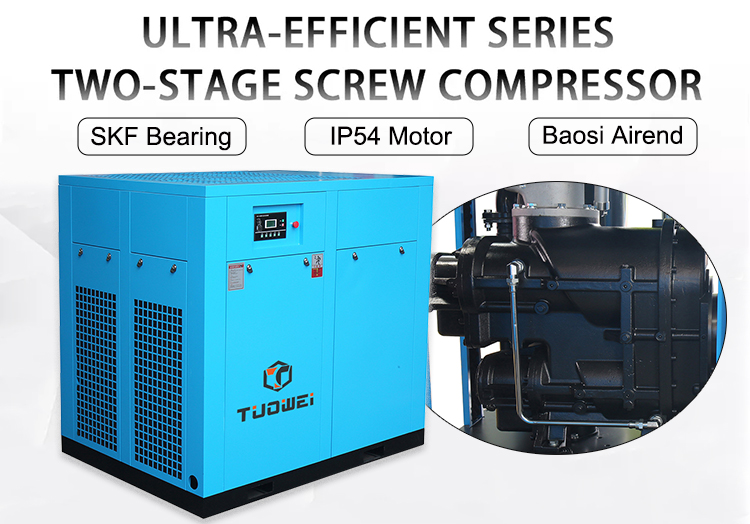

Aivyter presents the Oil Injected Rotary Twin Screw Air Compressor. This machine offers versatile performance with multiple pressure options.

The compressor operates at 7, 8, 10, or 13 bar pressure. Air delivery ranges from 5.3 to 7.2 m3/min depending on pressure.

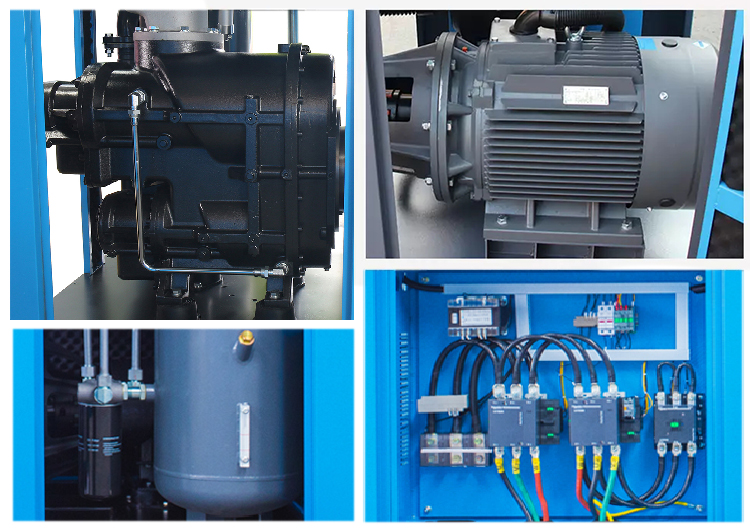

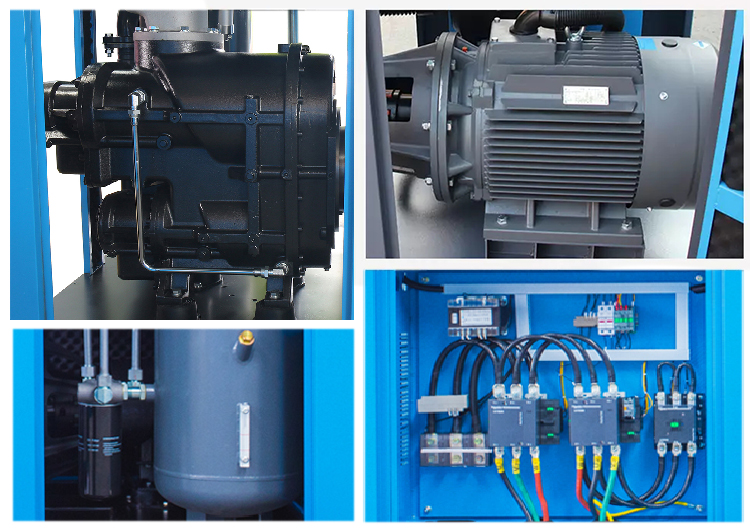

It features a 30kw motor with IP54 protection. The unit uses a Baosi airend for reliable operation.

Designed for 380v/50Hz power supply, it weighs 1900kgs. The compressor's dimensions are 1900x1250x1570mm.

With a noise level of 68dB(a), it provides quiet operation. The G2" pipe diameter ensures efficient air flow.

This direct-driven compressor uses SKF brand bearings. It offers energy-saving advantages for cost-effective use.

The unit comes in customizable colors to suit your preferences. Standard export wooden packaging ensures safe transportation.

Product Features

Two-stage compression

Divides compression into two stages

Reduces compression ratio per stage

Lowers required drive power

Intermediate cooling

Uses warm oil to cool gas between stages

Reduces gas temperature before next stage

Improves compression efficiency

Friction management

Addresses gas temperature rise due to friction

Minimizes pressure increase from temperature rise

Reduces extra power needed for compression

Coolant injection

Equipped with coolant injection curtain device

Helps maintain optimal operating temperature

Enhances overall system efficiency

Intermeshing rotors

Core component for air compression

Reduces air volume to create pressure

Ensures efficient compression process

Oil-injected design

Provides smooth rotor operation

Lubricates internal components

Assists in cooling the system

Compact design

Space-saving construction

Easy to install in various settings

Simplifies facility planning

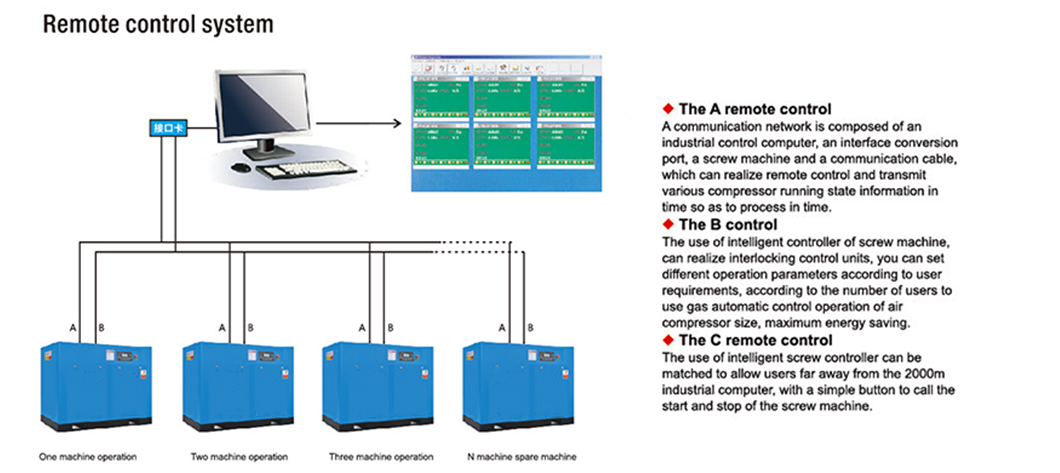

User-friendly control

Features accessible control panel

Allows performance monitoring

Enables easy adjustments to meet specific needs

Durable construction

Built with high-quality components

Withstands industrial use demands

Ensures long-term reliability

Versatile application

Suitable for various industrial uses

Delivers consistent performance

Adapts to different operational requirements

Product Parameters:

| Model | Working Pressure | Capacity | Motor Power | Dimension

(mm) | Net Weight

(KGS) | Air Outlet |

| psi | bar | cfm | m3/min | kW/hp |

| SGD 15II | 100 | 7 | 105.9 | 3.0 | 15/20 | 1480*920*1190 | 520 | G1 |

| 116 | 8 | 102.4 | 2.9 |

| 145 | 10 | 84.7 | 2.4 |

| 174 | 12 | 77.7 | 2.2 |

| SGD 18II | 100 | 7 | 127.1 | 3.6 | 18.5/25 | 1480*920*1190 | 520 | G1 |

| 116 | 8 | 123.6 | 3.5 |

| 145 | 10 | 102.4 | 2.9 |

| 174 | 12 | 88.3 | 2.5 |

| SGD22II | 100 | 7 | 148.3 | 4.2 | 22/30 | 1480*920*1190 | 520 | G1 |

| 116 | 8 | 144.8 | 4.1 |

| 145 | 10 | 123.6 | 3.5 |

| 174 | 12 | 113.0 | 3.2 |

| SGD30II | 102 | 7 | 229.5 | 6.5 | 30/40 | 1660*1085*1400 | 750 | G1 1/2 |

| 116 | 8 | 226.0 | 6.4 |

| 145 | 10 | 173.0 | 4.9 |

| 174 | 12 | 148.3 | 4.2 |

| SGD37II | 102 | 7 | 254.2 | 7.2 | 37/50 | 1660*1085*1400 | 750 | G1 1/2 |

| 116 | 8 | 250.7 | 7.1 |

| 145 | 10 | 222.5 | 6.3 |

| 174 | 12 | 190.7 | 5.4 |

| SGD45II | 102 | 7 | 346.0 | 9.8 | 45/60 | 2100*1360*1740 | 1510 | G2 |

| 116 | 8 | 342.5 | 9.7 |

| 145 | 10 | 275.4 | 7.8 |

| 174 | 12 | 229.5 | 6.5 |

| SGD55II | 102 | 7 | 452.0 | 12.8 | 55/75 | 2100*1360*1740 | 1510 | G2 1/2 |

| 116 | 8 | 441.4 | 12.5 |

| 145 | 10 | 339.0 | 9.6 |

| 174 | 12 | 303.7 | 8.6 |

| SGD75II | 102 | 7 | 617.9 | 17.5 | 75/100 | 2100*1360*1740 | 1530 | G2 1/2 |

| 116 | 8 | 582.6 | 16.5 |

| 145 | 10 | 441.4 | 12.5 |

| 174 | 12 | 395.5 | 11.2 |

| SGD90II | 102 | 7 | 734.4 | 20.8 | 90/120 | 2300*1470*1840 | 1940 | G2 1/2 |

| 116 | 8 | 699.1 | 19.8 |

| 145 | 10 | 596.7 | 16.9 |

| 174 | 12 | 504.9 | 14.3 |

| SGD110II | 102 | 7 | 865.1 | 24.5 | 110/150 | 2300*1470*1840 | 2400 | G2 1/2 |

| 116 | 8 | 829.8 | 23.5 |

| 145 | 10 | 695.6 | 19.7 |

| 174 | 12 | 621.5 | 17.6 |

| SGD132II | 102 | 7 | 1059.3 | 30.0 | 132/175 | 2300*1470*1840 | 2400 | G2 1/2 |

| 116 | 8 | 988.7 | 28.0 |

| 145 | 10 | 829.8 | 23.5 |

| 174 | 12 | 699.1 | 19.8 |

| SGD160II | 102 | 7 | 1218.2 | 34.5 | 160/200 | 2850*1600*2000 | 5350 | G2 1/2 |

| 116 | 8 | 1186.4 | 33.6 |

| 145 | 10 | 1059.3 | 30.0 |

| 174 | 12 | 840.4 | 23.8 |

| SGD185II | 102 | 7 | 1447.7 | 41.0 | 185/250 | 3600*2100*2190 | 5450 | DN100 |

| 116 | 8 | 1355.9 | 38.4 |

| 145 | 10 | 1147.6 | 32.5 |

| 174 | 12 | 1009.9 | 28.6 |

| SGD220II | 102 | 7 | 1716.1 | 48.6 | 220/300 | 3800*1980*2150 | 6500 | DN125 |

| 116 | 8 | 1659.6 | 47.0 |

| 145 | 10 | 1447.7 | 41.0 |

| 174 | 12 | 1341.8 | 38.0 |

| SGD250II | 102 | 7 | 1942.1 | 55.0 | 250/350 | 3800*1980*2150 | 6600 | DN125 |

| 116 | 8 | 1906.7 | 54.0 |

| 145 | 10 | 1624.3 | 46.0 |

| 174 | 12 | 1412.4 | 40.0 |

Company Information:

Fujian Aivyter Compressor Co., Ltd., was established in 2011, and located in Fuzhou China, is a professional enterprise engaged in the research, development, sale and service of screw air compressor, oil free screw air compressor, portable diesel engine screw air compressor, air dryer, precision filters, gas generator, gas booster compressor and engineering construction equipment.

After more than ten years of development, the shareholders have established three factories during this period, namely Fuzhou Aivyter Mechanical & Electrical Equipment Co., Ltd, Hebei Tucheng Tunnel Equipment Co., Ltd., and Fujian Aivyter Intelligent Equipment Co., Ltd. The annual output value is 300 million yuan. There are nearly 200 employees. Among them, there are 20 technical R&D personnel and 70 technicians in after-sales service team. 7 sales personnel in international business department.

Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss clients’ requirements and ensure full customer satisfaction by supplying high-quality construction equipment. Aivyter company not only has its own import and export right and stable distributors worldwide, but also has a team of professional after sales and service. In addition, we have obtained CE, TUV, SGS, ISO certificates.

Whether you're looking for a compressed air system for your manufacturing facility, automotive shop, or other industrial application, the Oil Injected Rotary Twin Screw Air Compressor is the perfect choice. With its high-performance capabilities, reliable operation, and easy maintenance, this compressor is sure to provide the compressed air you need to get the job done efficiently and effectively.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara