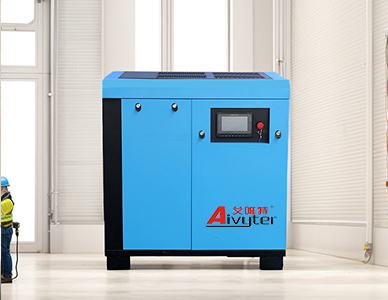

A Variable Frequency Drive (VFD) compressor is an advanced type of air compressor that incorporates a variable frequency drive system to control the speed of the compressor's motor. This technology allows the compressor to adjust its output based on the air demand, rather than running at a constant speed regardless of demand.

Importance of Energy Efficiency:

In today's highly competitive business landscape, managing operational costs is more critical than ever, particularly when it comes to power consumption. Traditional air compressors are known for their high energy usage, which can significantly inflate power bills. As companies strive to enhance their profitability, reducing these energy costs has become a priority. Energy-efficient solutions are not just a matter of reducing expenses but also contribute to environmental sustainability and overall operational efficiency.

VFD Compressor Technology:

Definition: A Variable Frequency Drive (VFD) is an advanced electronic module that controls the speed of an air compressor's motor by varying the frequency of the electrical power supplied to it. This technology allows for precise control of the motor’s speed and, consequently, the compressor’s output. By adjusting the speed of the compressor to match the demand for compressed air, VFDs help optimize power consumption.

Benefits: Implementing VFD technology converts traditional, energy-intensive compressors into highly efficient units. VFD compressors offer the flexibility to adjust their speed according to real-time air demand, which leads to a significant reduction in energy consumption compared to fixed-speed compressors that run at full capacity continuously. This dynamic adjustment minimizes wasted energy during periods of low demand, resulting in more efficient operation and lower energy costs.

Energy Savings:

Lifecycle Costs: Energy consumption accounts for up to 85% of an air compressor's total lifecycle cost. This highlights the substantial impact that energy efficiency can have on overall expenses. The cost of energy used throughout the compressor's operational life far outweighs the initial purchase and maintenance costs.

Cost Reduction: Incorporating VFDs into air compressor systems can lead to average energy savings of approximately 18%. These savings can be even more pronounced in certain scenarios, demonstrating that VFD technology offers a significant return on investment. By reducing energy consumption, companies not only cut down on their utility bills but also enhance the efficiency and sustainability of their operations.

Key Features of VFD Compressors

Variable Speed Control:

Function:VFD compressors incorporate a variable frequency drive (VFD) that precisely controls the speed of the compressor motor. Unlike traditional compressors that operate at a constant speed regardless of demand, VFD compressors adjust their motor speed to match the actual air demand. This flexibility allows the compressor to operate efficiently at varying speeds, optimizing performance and energy use based on current needs. This capability ensures that the compressor provides only the necessary amount of compressed air, avoiding unnecessary energy expenditure and wear.

Energy Efficiency:

Benefit: By varying the motor speed according to demand, VFD compressors can significantly cut down on energy consumption compared to fixed-speed compressors that run at full capacity all the time. This efficiency translates into substantial cost savings on energy bills, particularly in applications with fluctuating air requirements. The ability to adapt to lower speeds when demand is reduced helps in minimizing energy usage, leading to a more cost-effective operation over time.

Improved Performance:

Advantage: VFD compressors are designed to maintain consistent air pressure and flow despite variations in demand. This stability enhances the overall performance of the compressed air system, ensuring reliable operation for processes that require precise and stable air pressure. By effectively handling variable loads, VFD compressors contribute to improved process efficiency and product quality, as they can meet the precise air demands of different industrial applications.

Reduced Wear and Tear:

Benefit: Operating at variable speeds reduces the mechanical stress and strain on the compressor components. This lessens the wear and tear on moving parts, which can extend the lifespan of the compressor and decrease the frequency and cost of maintenance. By avoiding the constant start-stop cycles typical of fixed-speed compressors, VFD compressors experience fewer mechanical issues, leading to a more durable and reliable system.

Lower Noise Levels:

Advantage: VFD compressors offer quieter operation compared to traditional fixed-speed models, particularly because they can run at lower speeds when air demand is low. The ability to modulate speed helps to reduce noise levels, making VFD compressors ideal for environments where noise is a concern. This feature not only contributes to a more comfortable working environment but also helps in complying with noise regulations in sensitive areas.

Case Studies:

Pharmaceutical Industry: A Chennai-based pharmaceutical company retrofit their existing air compressors with VFDs, resulting in a remarkable 37% reduction in energy costs. This retrofit allowed them to achieve a return on investment (ROI) in just 10 months. The VFD's ability to adjust compressor speed according to actual demand significantly cut down on unnecessary energy use, leading to substantial savings.

Automobile Industry: Another Chennai-based company, operating in the automobile sector, experienced a 40% decrease in energy costs after installing VFDs. They achieved ROI in just 6 months. In addition to the significant cost savings, the reduced heat generation from the VFDs contributed to extended equipment longevity, enhancing the lifespan of critical components like intake valves and air oil separators.

How VFD Works:

Variable Load Management: VFDs manage power consumption efficiently by adjusting the compressor’s speed to align with varying air demand. This means that during periods of lower demand, the compressor operates at reduced speed, consuming less power and minimizing energy waste.

Efficiency Gains: By eliminating the unload cycle—a period when the compressor is running without delivering air—VFDs significantly cut energy waste. This continuous adjustment according to real-time demand helps in maintaining operational efficiency and reducing unnecessary power consumption.

Energy Savings Opportunities:

Unload Cycle Elimination: VFDs offer up to 25% energy savings by removing the energy waste associated with unload cycles. Traditional compressors consume power even when not actively compressing air, but VFDs keep energy use proportional to actual demand.

Pressure Reduction: Maintaining consistent pressure with a VFD compressor can save approximately 7% in energy costs. This is achieved by avoiding the extra energy required to compress air to higher pressure levels that are typically needed in fixed-speed compressors.

Leakage Reduction: VFDs can also deliver up to 3% in energy savings by minimizing air leakage and pressure drop losses. By maintaining constant pressure, VFD compressors reduce the energy lost through leaks and pressure drops, contributing to overall energy efficiency.

Choosing and Retrofitting VFD Compressors:

Assessment: To identify potential energy savings, evaluate compressor run and unload hours using HMI/hr meters. This data helps determine if a VFD retrofit will be beneficial.

Selection: Choose compressors for VFD retrofitting based on their base and trim load requirements. Conducting an energy audit is crucial for accurate measurements of these loads and ensuring the best fit for your energy-saving goals.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara