Product Specification

| Parameter | Value |

| Color | Blue |

| Pressure | 12bar, 16bar |

| Weight | 16kg |

| Input Output Inch | 2 1/2'' |

| Capacity | 15m³/min |

| Oil Filtration Content | 0.01 ppm |

| Precision Filter | 3μm / 1μm / 0.01μm |

| Filter Material | Multi-layer non-woven fabric + glass fiber |

| Application Industry | Hotel, Clothing Shop, Building Material Shop, Factory, |

| Machinery Workshop, Food & Beverage Factory, Farm, |

| Restaurant, Home, Retail, Food Store, Printing Shop, |

| Construction Work, Energy & Mining, Food & Beverage Shop, |

| Advertising Company |

| Payment Methods | L/C, T/T, Western Union |

| Delivery Time | 7 ~ 25 days |

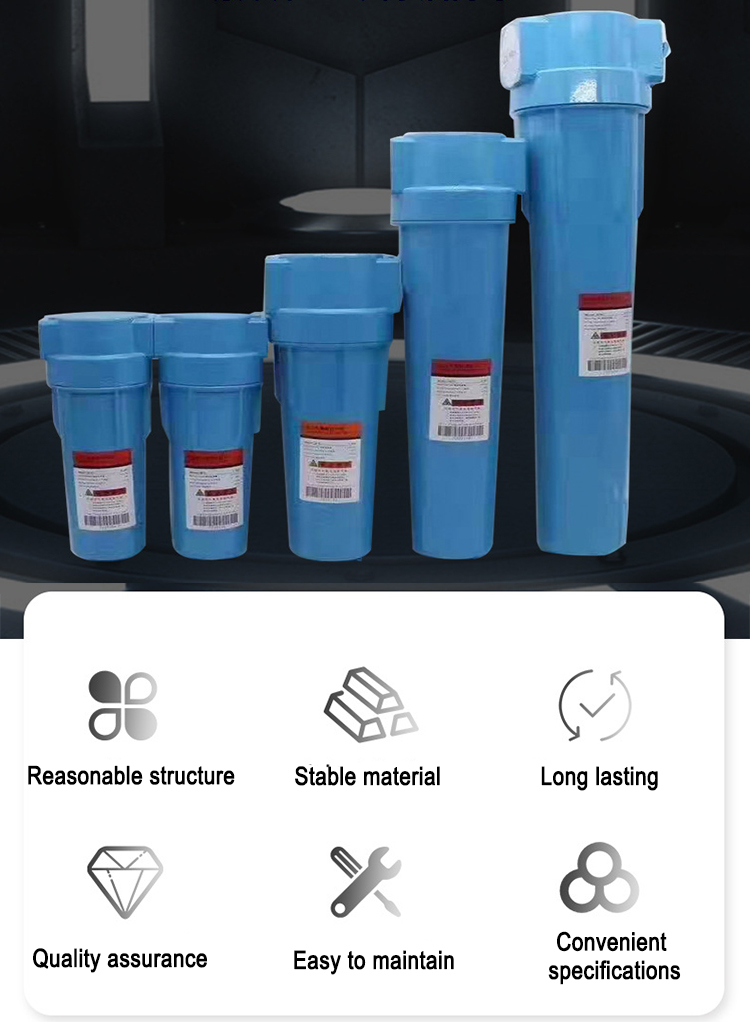

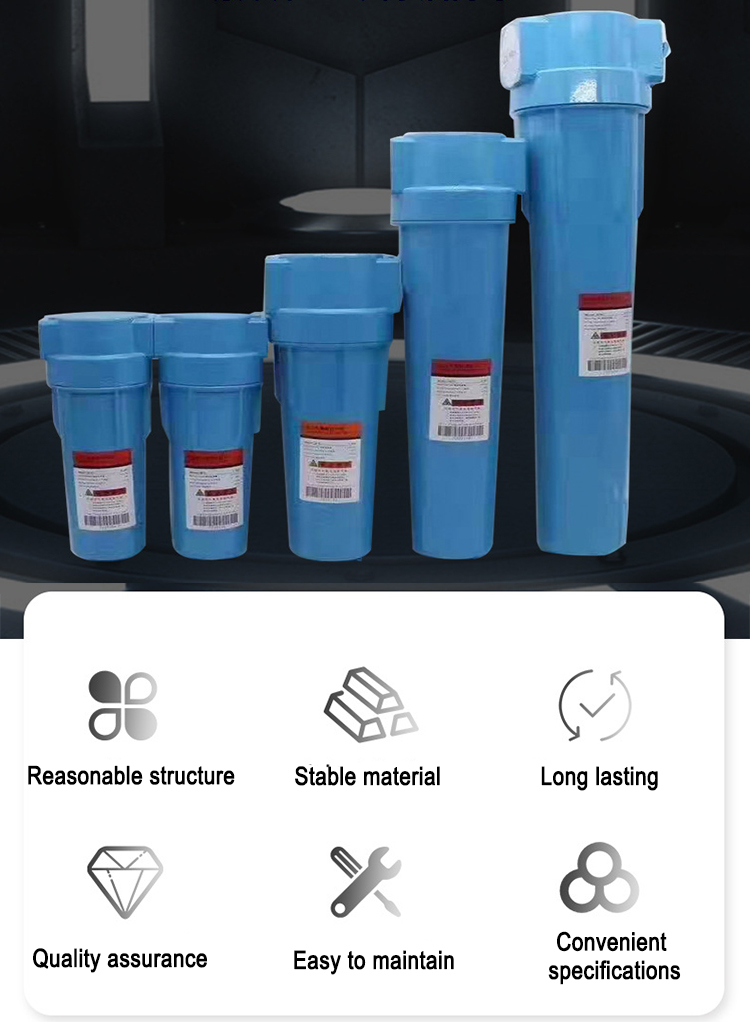

The Precision Compressed Air Filter is designed for efficient air filtration. Its blue casing ensures durability and reliability.

The filter operates at pressures of 12bar and 16bar. It weighs 16kg, making it compact and manageable.

The input and output connection size is 2 1/2 inches. The filter handles an air capacity of 15m³/min.

It achieves oil filtration at 0.01 ppm. Filtration precision is available at 3μm, 1μm, and 0.01μm.

The filter material combines multi-layer non-woven fabric and glass fiber. This ensures high filtration performance.

It serves various industries, including hotels, factories, farms, and food and beverage shops. Other uses include clothing shops, printing, and construction work.

The product supports payment via L/C, T/T, or Western Union. Delivery time ranges from 7 to 25 days.

This air filter is ideal for businesses needing clean and efficient compressed air.

Precision Compressed Air Filter for Screw Air Compressor

Compressed Air Precision Filter:

This filter removes contaminants from compressed air systems, including:

It consists of a filter element, housing, end cover, and rack. The filter material typically matches the connecting pipeline. Options include cast iron, carbon steel, low alloy steel, and stainless steel, based on usage conditions.

This filter ensures clean, high-quality air for compressor systems across various applications.

Product Features

The Precision Compressed Air Filter is ideal for clean and effective air filtration when used in any industry. It is built to withstand years of usage and performance. It comes with features such as simple installation, self-draining feature, and corrosion-resistant body construction.

Easy Installation

Precision made screw threads facilitate ease on the fastening and unfastening of the fitting or replacing it with another one.

Pressure Indicator

A differential pressure window and a sight glass are provided for the purpose of monitoring.

Automatically Drained

An efficient inbuilt automatic drainer is provided for the removal of excess water.

Anti-Corrosion Interior

Anti-corrosive internal filter housing is incorporated for protection against rusting and damage.

High-Pressure Operation

Capable of operating pressure of 1.3Mpa for harsh applications.

Heat Resistance

The material is designed to work at high temperatures of 120 degrees centigrade and below.

Advantages of Precision Compressed Air Filter for Screw Air Compressor

Aivyter, as an expert in air filtration solutions for compressors, guarantees a highly efficient filtration of any airborne impurities even under conditions of extensive utilization. Learn about the main advantages of air compressors manufactured by Aivyter and how they increase the performance and reliability of the air compressor.

High-Quality Materials

Each is Precision Processed and made of the appropriate raw materials as per specification to ensure the correct operations of the unit.

Effective Filtration

Filters effectively remove oil from compressed air, ensuring better cleanliness in the output.

Durable Filter Element

A thickened imported fiber filter element delivers steadfast filtration efficiency.

Activated Carbon Technology

An authentic activated carbon filter guarantees high-level air deodorization.

Customer assurance.

Provides a 7-day replacement period for quality control.

Corrosion Resistance Case

The aluminum alloy casing is not prone to rusting and application of the casing minimizes the differential pressure.

How to choose the right filter?

1. Inlet and outlet size: In principle, the inlet and outlet size of the filter should not be smaller than the inlet size of the matching pump, and it is generally the same as the intersection of the inlet pipe.

2. Working pressure: Determine the pressure level of the filter according to the maximum pressure that may appear in the filter pipeline.

3. Filtration level: Mainly consider the size of the particles to be intercepted, depending on the process requirements of the medium flow rate. You can check the screen size of various sizes and check the screen size.

4. Air handling capacity: The large air handling capacity is based on the working pressure of 0.7-1.0Mpa.

5. Filter material: The filter material is generally the same as the material used to connect the process pipeline. For different use conditions, cast iron, carbon steel, low alloy steel or stainless steel filters can be considered.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara