37KW 50HP 0.8Mpa PM Oil Lubricated Screw Air Compressor

Featuring advanced screw compressor technology, this model is designed to deliver efficient and reliable performance, ensuring that you can meet your production targets with ease. The use of high-quality lubricating oil ensures that the compressor's components stay well-lubricated, extending the lifespan of the machine.

With a maximum working pressure of 0.8Mpa, this air compressor is capable of providing high-quality compressed air for a range of applications. Its 37KW 50HP motor provides powerful and consistent performance, enabling you to maximize your productivity and minimize downtime.

The PM (Permanent Magnet) motor technology used in this air compressor ensures that it operates with maximum efficiency, reducing energy costs and minimizing your carbon footprint. Additionally, the compact design of the compressor makes it easy to install and maintain, reducing your overall maintenance costs.

Investing in the 37KW 50HP 0.8Mpa PM Oil Lubricated Screw Air Compressor is a smart choice for any business looking to improve its production efficiency, reduce operating costs, and enhance the quality of their products. With its advanced technology, reliable performance, and low maintenance requirements, this compressor is sure to exceed your expectations. And with our commitment to customer satisfaction and support, you can rest assured that your investment is well-protected.

Permanent Magnet Frequency Conversion Screw Compressor(PM Screw Air Compressor )

VSD screw air compressors are suitable for customers who need diferent amount of air supply and extremely accurate pressure. It can facilitate customers to optimize production process and improve productivity.

The principle of VSD is to adjust the motor rotation speed automatically according to the actual air demand. The reduced system pressure decreases the total energy consumption of the whole system, which can reduce energy costs by 35% or more.

The VSD air compressor reduces the energy consumption through the following points

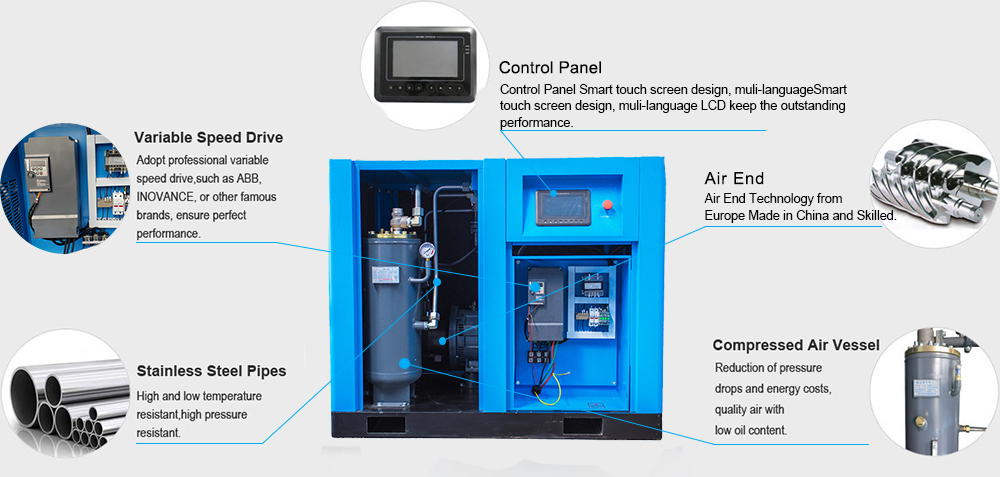

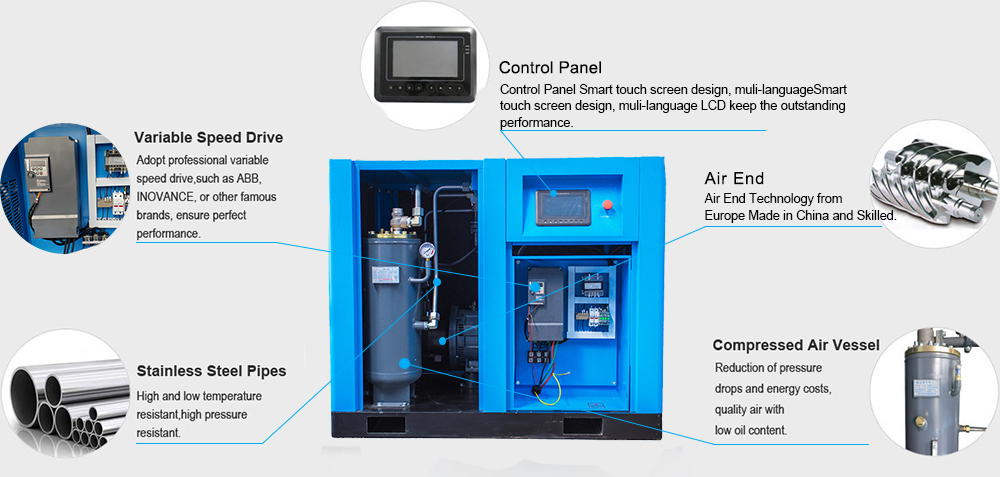

Air End: Utilizes 3rd generation 5:6 rotors with optimized European profiles. Ensures low noise, low energy consumption, and long service life.

Motor: Equipped with a custom low RPM motor and SKF bearings. Achieves 3%-5% higher efficiency than competitors.

Oil Filter: Features aerospace design revolving oil filter. Offers superior filtering and prolongs air end lifespan.

Oil-Air Separator: Includes a large volume tank and advanced three-stage separator. Ensures compressed air quality with less than 3ppm oil content.

Air Filter: Designed for high dust holding and low flow resistance. Effectively filters micro particles for optimal system performance.

Air Inlet Valve: Adjustable between 0-100%. Enhances service life with a volume adjustment valve.

Electronic Control System: Intelligent microcomputer system with fault diagnosis and protection. Capable of continuous 24-hour operation.

7.5kw ~ 160kw permanent magnet variable frequency screw air compressor parameters

| Model | Motor Power | Working Pressure | Capacity | Lubricating oil quantity (L) | Driven Method | Cooling Method | Noise (dB) | Dimension(mm) | Net Weight | Air Outlet Pipe Diameter |

| kw/hp | bar | m3/min | L*W*H | KGS |

| SGPM08 | 7.5/10 | 7 | 1.2 | 10 | Direct Drive | Air Cooling / Water Cooling | 66±2 | 900*670*850 | 220 | 1/2’’ |

| 8 | 1.1 |

| 10 | 0.95 |

| 12 | 0.8 |

| SGPM11 | 11/15 | 7 | 1.65 | 18 | 68±2 | 1000*750*1015 | 300 | 3/4’’ |

| 8 | 1.5 |

| 10 | 1.3 |

| 12 | 1.1 |

| SGPM15 | 15/20 | 7 | 2.5 | 18 | 68±2 | 1000*750*1015 | 300 | 3/4’’ |

| 8 | 2.3 |

| 10 | 2.1 |

| 12 | 1.9 |

| SGPM18 | 18.5/25 | 7 | 3.2 | 18 | 68±2 | 1130*850*1175 | 480 | 1’’ |

| 8 | 3 |

| 10 | 2.7 |

| 12 | 2.4 |

| SGPM22 | 22/30 | 7 | 3.8 | 18 | 68±2 | 1130*850*1175 | 480 | 1’’ |

| 8 | 3.6 |

| 10 | 3.2 |

| 12 | 2.7 |

| SGPM30 | 30/40 | 7 | 5.3 | 18 | 68±2 | 1130*850*1175 | 480 | 1’’ |

| 8 | 5 |

| 10 | 4.5 |

| 12 | 4 |

| SGPM37 | 37/50 | 7 | 6.8 | 30 | 68±2 | 1250*1000*1335 | 500 | 11/2" |

| 8 | 6.2 |

| 10 | 5.6 |

| 12 | 5 |

| SGPM45 | 45/60 | 7 | 7.4 | 30 | 72±2 | 1250*1000*1335 | 500 | 11/2" |

| 8 | 7 |

| 10 | 6.2 |

| 12 | 5.6 |

| SGPM55 | 55/75 | 7 | 10 | 65 | 72±2 | 1800*1250*1670 | 1200 | 2" |

| 8 | 9.6 |

| 10 | 8.5 |

| 12 | 7.6 |

| SGPM75 | 75/100 | 7 | 13.4 | 65 | 72±2 | 1800*1250*1670 | 1200 | 2" |

| 8 | 12.6 |

| 10 | 11.2 |

| 12 | 10 |

| SGPM90 | 90/120 | 7 | 16.2 | 72 | 72±2 | 1800*1250*1670 | 1200 | 2" |

| 8 | 15 |

| 10 | 13.8 |

| 12 | 12.3 |

| SGPM110 | 110/150 | 7 | 21 | 90 | 72±2 | 2300*1470*1840 | 2000 | DN85 |

| 8 | 19.8 |

| 10 | 17.4 |

| 12 | 14.8 |

| SGPM132 | 132/175 | 7 | 24.5 | 90 | 75±2 | 2300*1470*1840 | 2000 | DN85 |

| 8 | 23.2 |

| 10 | 20.5 |

| 12 | 17.4 |

| SGPM160 | 160/200 | 7 | 28.7 | 110 | 75±2 | 2500*1470*1840 | 3200 | DN85 |

| 8 | 27.6 |

| 10 | 24.6 |

| 12 | 21.5 |

| SGPM185 | 185/250 | 7 | 32 | 110 | 75±2 | 2500*1470*1840 | 3200 | DN85 |

| 8 | 30.4 |

| 10 | 27.4 |

| 12 | 24.8 |

Fujian Aivyter Compressor Co., Ltd., was established in 2011, and located in Fuzhou China, is a professional enterprise engaged in the research, development, sale and service of screw air compressor, oil free screw air compressor, portable diesel engine screw air compressor, air dryer, precision filters, gas generator, gas booster compressor and engineering construction equipment.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara