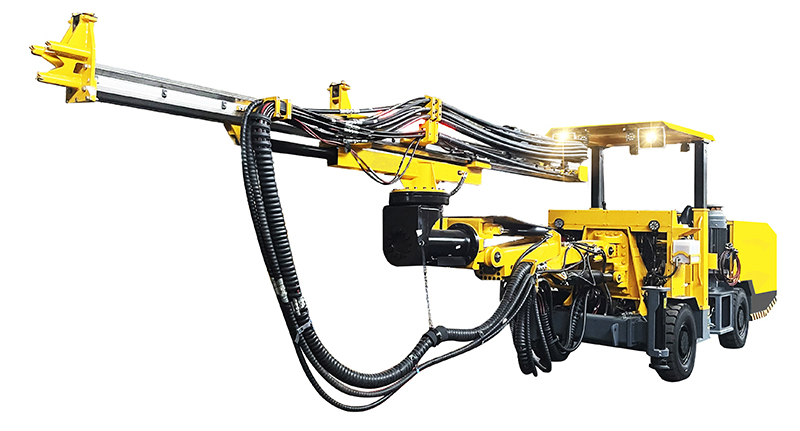

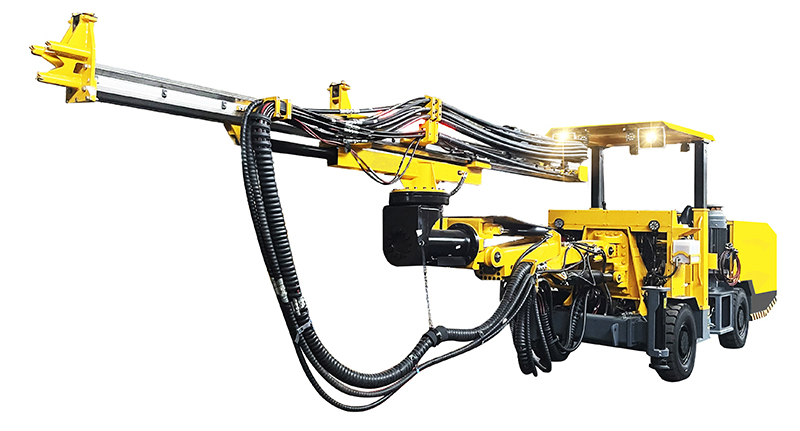

AZT1-6500 mining hydraulic rock drilling rig is a multifunctional equipment designed for various mining and construction applications.

1. Wide application: This hydraulic rock drilling rig is not limited to mining metal ores, radioactive ores, as well as mines and tailings ponds used as petrochemical raw materials, building materials, auxiliary raw materials, refractory materials, and other non-metallic minerals (excluding coal). It can also be widely used in water conservancy and hydropower projects, highway and railway tunnels, and chemical industry environments.

2. Adaptability to rock types: Its design can handle various rock layers, and the Pugh hardness coefficient (f) ranges from 6 to 16, indicating its suitability for harder rock types.

3. Compact design for confined spaces: Despite its powerful functionality, the design of this vehicle allows for efficient operation within narrow tunnel widths, with a minimum requirement of only 3 * 3 meters, making it an ideal choice for confined spaces.

4. Multi directional rotation: The thruster's ability to rotate 360 ° in both horizontal and vertical planes provides unparalleled flexibility in drilling direction, which is crucial for precise drilling in narrow spaces.

5. Functional Capability: In addition to standard drilling, this drilling rig is also equipped with the function of drilling anchor holes, enhancing its practicality in various mining and construction tasks.

6. Hydraulic power: Fully hydraulic double triangle telescope boom, single stage telescope, telescope stroke single arm 1250mm, big arm lifting 60 ° and lowering 30 °, big and small arms can be automatically leveled. Large working surface range: single arm excavation height 4500mm.

7. Safety and efficiency: The design and features of AZT1-6500 KA may prioritize safety standards and operational efficiency, which are crucial in underground and hazardous environments.

Basic Parameters of Drilling Jumbo - AZT1-6500

| Parameters of drill jumbo |

|

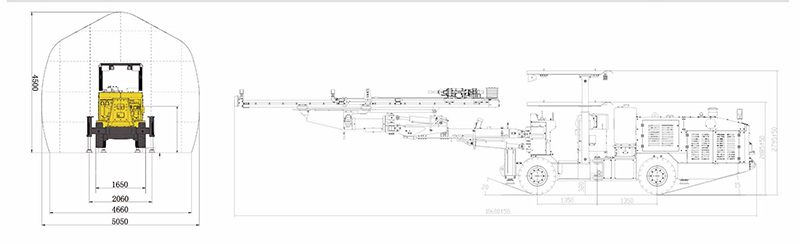

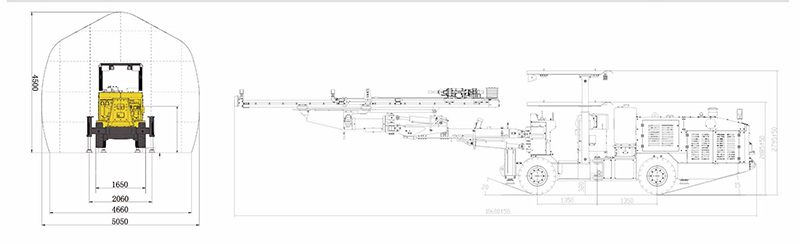

| Applicable section | 3000x3000-5050x6500 mm |

| Dimensions L*W*H | 11000x1760x2525(3375)mm |

| Ground clearance | 330 mm |

| Minimum turning radius | Inside:3450/Outside: 5510mm |

| Climbing ability | 15° |

| Running speed | ≤7.2 kM/h |

| Cable length | 90 m |

| Weight | 12000 KGS |

| Specifications of rock drill |

|

| Rock drill | DZ622 |

| Impact power | 22 kw |

| Impact frequency | 62 Hz |

| Impact pressure | 130-200 bar |

| Rotary system | Independent rotation |

| Rotation speed | 0-275 r/min |

| Rotation torque (max) | 980 Nm |

| Thruster |

|

| Total length | 5800 mm |

| Drill rod length | 4300/3700 mm |

| Depth of hole | 4000/3400 mm |

| Propulsion force | 15 KN |

| Drilling arm |

|

| Compensation itinerary | 1400 mm |

| Horizontal hole | Complete coverage |

| Sliding frame rotation | ±180° |

| Pitch angle | +60°/-30° |

| Swing angle | ±35° |

| Drilling arm weight | 2000 kg |

| Hydro-pneumatic system |

|

| Maximum displacement of water pump (12 bar) | 4 m³/h |

| Air flow | 0.55 m³/min |

| Electrical system |

|

| Total installed power | 65 kW |

| Main motor power | 55 kW |

| Voltage | 380V(Customizable) |

| Hydraulic system |

|

| Closed hydrostatic drive walking system |

|

| Hydraulic direct control operating system |

|

| Equipped with anti-stuck function |

|

| Chassis |

|

| Diesel engine | Cummins |

| Rated output power (2200r/min) | 66 kW |

Boom system: Fully hydraulic double triangle telescopic boom, single-stage telescopic, telescopic stroke single arm 1400mm, big arm lifting 60° and lowering 30°, big and small arms can be automatically leveled. Large working surface range: single arm excavation height 4500mm.

The propulsion, impact and rotation of the entire rock drill are all controlled by hydraulics. Compared with electric hydraulic control, it has faster response speed, lower failure rate, and lower wear and tear on drill rods and drill bits.

Engineering chassis, good rigidity and strength, engineering axle, hydraulic gearbox, stable performance, low failure rate, easy maintenance.

60KW water-cooled turbocharged engine, strong power, climbing grade>18°; good passability, minimum ground clearance 350mm.

Different drill rods such as 3700/4300 can be selected according to customer needs.

The propulsion beam adopts an aluminum alloy frame with strong bending and torsion resistance.

Using well-known domestic brands of high-power rock drills.

| Impact performance | Rotation performance |

| Maximum impact power | 18KW | Rotary system | Independent rotation |

| Maximum pressure | 200bar | Rotation speed | 0-220 r/min |

| Impact frequency | 57HZ | Rotation torque (max) | 1050 Nm |

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara