SGM Series Smart Energy-Saving Water LubricatingOil-Free Screw Compressor

Self-learning function, intelligent start/stop;

Detect the ambient temperature to prevent the ambient temperature frombeing too high temperature to cause high--temperature failure:

Detect the terminal pressure of the post-treatment equipment to effectivelprevent the compressed air's pressure different from being too high to wasteelectric energy

Detect the motor's temperature to protect it.

The Rotary Horizontal Closed Type Oil Free Screw Air Compressor is a high-performance and durable air compressor that can meet the demands of various industries. Its oil-free design ensures that the compressed air is clean and free from contaminants, making it ideal for applications that require high-quality air, such as food and beverage, pharmaceuticals, electronics, and others.

Safety:

The Rotary Horizontal Closed Type Oil Free Screw Air Compressor is designed with safety in mind. Its advanced control system and safety features, such as explosion-proof and overheat protection, ensure that it operates safely and reliably at all times.

Advantages:

Water serves as lubricant, sealant, and coolant, simplifying the system

High capacity and low operating speed ensure reliable performance

Low compression temperature of approximately 40°C reduces energy consumption

Intelligent start/stop with self-learning function adapts to varying demand

Minimal noise, vibration, and no speed-up gear create a quiet work environment

Efficient air separation maintains compressed air quality

Oil-free design eliminates the need for waste oil disposal, promoting sustainability

Fewer spare parts, no oil filters or air/oil separators, and easy assembly reduce maintenance costs

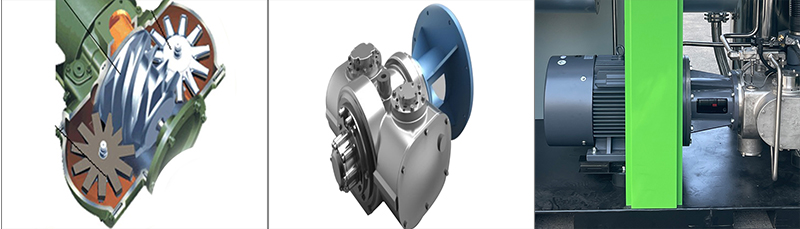

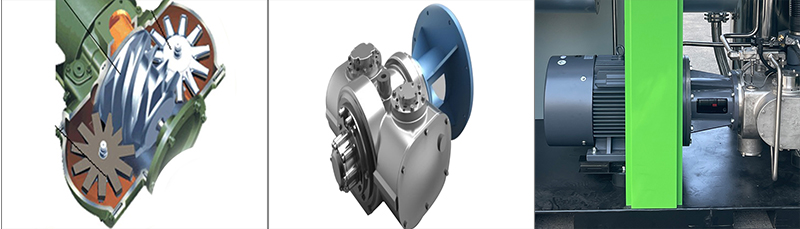

1.Water-lubricated Oil-free Compressor Airend

The water lubricated screw air end features a door rotor made of PEEK, a strong and durable plastic. The rotor is constructed from stainless steel used in aerospace applications. It is produced using a new manufacturing process that ensures high precision.

2.Main Rotor Structure

The main rotor consists of a single screw that meshes with star wheels on each side to compress material. This design balances the mechanical forces, resulting in reduced vibration and noise during operation under pressure.

3.Direct Drive Electric Motor

The main airend connects to the electric motor's output shaft using a flexible coupling. This connection method reduces power loss during transmission to almost zero.

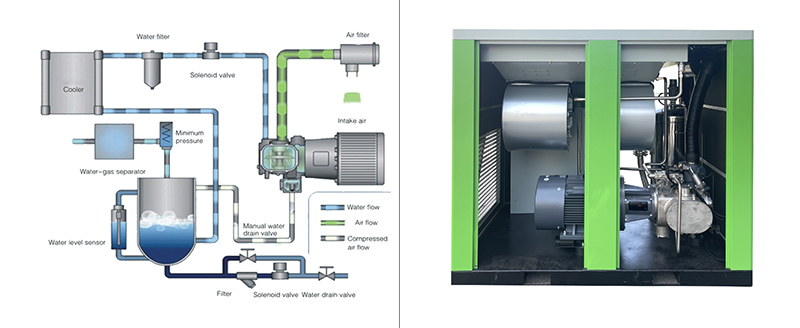

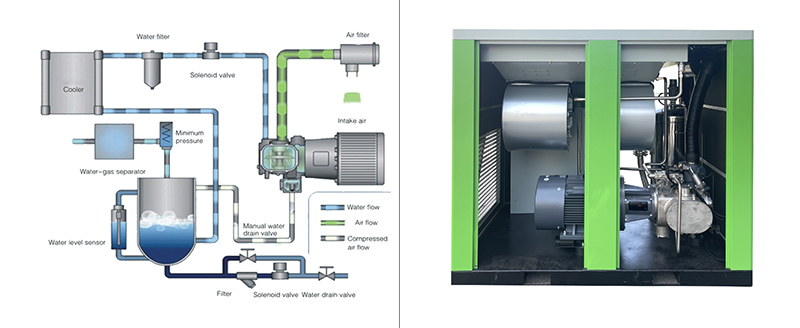

1.Only Need Water to lubricate

Water lubricated oil-free screw compressors use water to seal and lubricate the system. They run at reduced speeds and temperatures. The absence of lubricating oil ensures that the compressed air output is entirely clean and contains no oil.

2.Simple system process

The system consists of stainless steel and food grade control components. Parts such as the compressor air end, separation tank, connectors, filters, and water level controller are made from materials that resist corrosion. The system needs less maintenance and has a straightforward design.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara