What happens to compressed air when moisture is left untreated? If not properly managed, moisture in compressed air can cause significant damage to equipment, reduce efficiency, and even affect product quality. An air dryer for compressors is the solution to this problem, ensuring that moisture is effectively removed from compressed air systems.

In this article, we’ll explore how compressor air dryers work, the various types available, and their applications, helping you understand their importance in maintaining a reliable, efficient compressed air system.

What Is An Air Dryer for Compressor?

An air dryer for a compressor is a device that removes moisture from compressed air, ensuring it remains dry and free of water vapor. This prevents corrosion, damage to tools, and reduced efficiency in pneumatic systems. Common types include refrigerated, desiccant, and membrane dryers, each suited for different applications. Air dryers are essential in industries like manufacturing, automotive, and pharmaceuticals to maintain consistent air quality and equipment performance.

How do air dryers work?

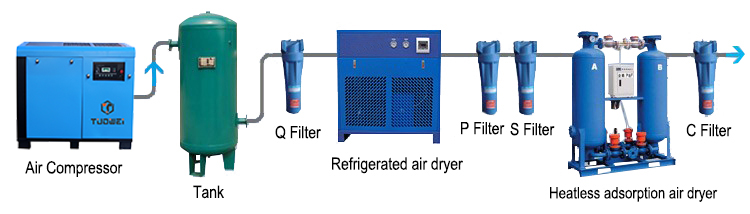

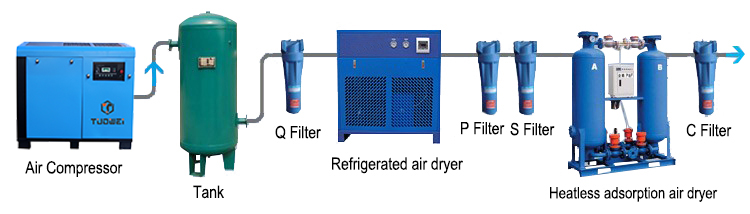

Air dryers in compressor systems remove moisture from compressed air to protect downstream equipment and processes. Refrigerated air dryers cool the compressed air to condense moisture, which is then separated and drained. The air is reheated before exiting the dryer to prevent condensation in the piping. These dryers are ideal for applications requiring moderate moisture removal, ensuring that air remains dry enough for most industrial uses.

Desiccant air dryers use moisture-absorbing materials, like silica gel, to adsorb water vapor from the compressed air. Regeneration of the desiccant material occurs by heating or pressure swing, allowing the dryer to achieve ultra-low dew points. These dryers are essential in industries requiring extremely dry air, such as pharmaceuticals, electronics, and food processing, where even trace moisture can cause damage or defects.

Types of Compressed Air Dryer

Refrigerated Air Dryers

Industrial Use Refrigerated Air Dryer for Screw Air Compressor

Applications:

Refrigerated air dryers are commonly used in industries where moderately dry air is sufficient. Applications include automotive repair shops, where dry air prevents moisture-related defects in painting and coating processes, and light manufacturing, where pneumatic tools and machinery require basic moisture control to maintain efficiency. These dryers are also popular in general-purpose air systems for factories, ensuring equipment longevity and consistent performance without requiring ultra-dry air.

Features:

Operates by cooling air to condense moisture

Cycling and non-cycling models available

Dew point: ~35–50°F (1.6–10°C)

Pros:

Cost-effective and reliable

Low maintenance requirements

Suitable for most non-critical industrial applications

Cons:

Refrigerated air dryers cool compressed air to around 35–50°F (1.6–10°C), causing moisture to condense and separate from the air. The dry air is then reheated before exiting, preventing condensation in downstream systems. These dryers are cost-effective and commonly used in industries with moderate dew point requirements, such as automotive repair and light manufacturing.

They are available in two variants: cycling and non-cycling. Cycling models adjust refrigeration based on demand, saving energy during low usage. Non-cycling models run continuously and are simpler to maintain but less energy-efficient. Refrigerated air dryers are reliable for applications not requiring extremely dry air.

Desiccant Air Dryers

Heated Desiccant Adsorption Air Dryer

Applications:

Desiccant air dryers are ideal for industries requiring ultra-dry air, such as pharmaceuticals, electronics, and aerospace. In pharmaceutical production, they ensure moisture-sensitive processes are not compromised, while in electronics manufacturing, they prevent corrosion or short-circuiting of components. Aerospace and defense sectors rely on these dryers for sub-zero environments, where even trace moisture can cause equipment malfunctions or freezing issues in air systems.

Features:

Uses desiccants like silica gel or activated alumina to adsorb moisture

Regeneration cycles via heat (heated) or pressure swing (heatless)

Dew point: as low as -40°F (-40°C) or lower

Pros:

Achieves extremely low dew points

Ideal for critical applications

Works well in sub-zero environments

Cons:

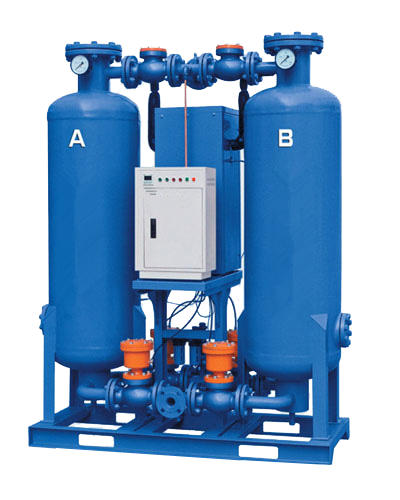

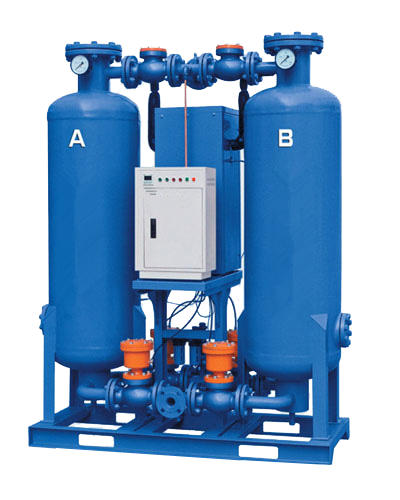

Desiccant air dryers use hygroscopic materials like silica gel or activated alumina to adsorb water vapor. They achieve ultra-low dew points as low as -40°F (-40°C) or even lower, making them ideal for critical industries like pharmaceuticals and electronics. These dryers operate in twin towers, alternating between drying and regeneration cycles.

Regeneration can occur through heat application (heated) or pressure swings (heatless). Heated models consume less compressed air but require more power, while heatless models are simple and energy-efficient for smaller systems. Their ability to provide extremely dry air makes them indispensable for sensitive processes.

Membrane Air Dryers

Applications:

Membrane air dryers excel in applications where portability, space-saving, or specialized moisture control is necessary. They are widely used in food packaging and processing industries to maintain product quality and prevent contamination. Additionally, instrumentation and precision tools benefit from the quiet, compact operation of membrane dryers, especially in remote or laboratory environments. Their versatility makes them a preferred choice for low-flow systems requiring moderate moisture removal.

Features:

Semi-permeable membranes separate water vapor

Compact and lightweight design

Dew point: Moderate, suitable for specific low-demand needs

Pros:

Energy-efficient with no moving parts

Quiet operation and minimal maintenance

Ideal for remote or portable applications

Cons:

Membrane air dryers use semi-permeable membranes to separate water vapor from compressed air. As air passes through the membrane fibers, moisture diffuses through the walls while dry air exits. They are compact, lightweight, and suitable for portable systems or low-flow applications where space is limited.

These dryers are energy-efficient and require minimal maintenance since they have no moving parts. However, they are best for specific applications requiring moderate moisture removal rather than high-volume industrial settings. Industries like food packaging and instrumentation benefit significantly from membrane air dryers.

Chemical Air Dryers

Applications:

Chemical air dryers are tailored for remote or off-grid locations where electricity is unavailable. They are often used in gas pipelines to prevent moisture from freezing or corroding the system. Additionally, they serve low-pressure air systems in remote industrial operations, providing simple and effective moisture control. Their straightforward design and reliance on chemical absorption make them ideal for specific low-demand applications.

Features:

Uses chemicals like calcium chloride to absorb moisture

Operates without electricity

Dew point: Dependent on chemical properties

Pros:

Simple operation and setup

Suitable for remote or power-limited locations

Cost-effective for specific low-demand applications

Cons:

Chemical air dryers rely on deliquescent chemicals like calcium chloride to absorb moisture directly from the compressed air. The chemical dissolves as it absorbs water, creating a brine solution that needs to be drained periodically. These dryers are simple and effective for specific low-flow applications.

They are best suited for operations in remote locations or where electricity is unavailable. However, the need for regular chemical replenishment can increase operational costs. Chemical air dryers are commonly used in gas pipelines or low-pressure air systems.

Deliquescent Air Dryers

Applications:

Deliquescent air dryers are commonly employed in outdoor or rugged environments such as oil and gas fields and construction sites. They help remove moisture from compressed air used in heavy equipment, preventing rust and wear. These dryers are also suitable for pipeline operations in cold climates, where their non-electric, durable design ensures reliable performance without the need for complex infrastructure or power sources.

Features:

Desiccant tablets absorb moisture and dissolve into brine

Non-electric and simple to maintain

Dew point: Moderate, depends on ambient temperature

Pros:

Low-maintenance and no power required

Durable for outdoor and rugged environments

Economical for basic applications

Cons:

Deliquescent air dryers are a specialized type of chemical dryer that use desiccant tablets to absorb water vapor from compressed air. As the tablets dissolve, they form a brine that collects at the bottom of the dryer for removal. They are ideal for outdoor applications and settings requiring simple moisture removal.

These dryers are low-maintenance and do not need electricity, making them suitable for remote locations. However, they provide limited control over dew points and are less effective for high-demand systems compared to other dryer types. They are often used in oil fields and construction sites.

Common Problems of Air Dryers in Compressed Air Systems and Troubleshooting Solutions

Insufficient Moisture Removal

Causes:

Overloaded air dryer due to increased air demand

High ambient temperature exceeding dryer capacity

Blocked or damaged moisture separators or filters

Solutions:

To resolve insufficient moisture removal, start by ensuring the air dryer is appropriately sized for the current air demand. Upgrade to a larger dryer if needed. Improve ambient conditions by enhancing ventilation or installing cooling systems to lower the temperature around the dryer. Regularly inspect and clean moisture separators and filters to prevent blockages that reduce efficiency. Pre-treat the air with aftercoolers to reduce moisture load before it enters the dryer, optimizing performance.

Excessive Pressure Drop

Causes:

Clogged filters or desiccant bed

Restricted airflow due to undersized piping or hoses

Fouled heat exchangers in refrigerated dryers

Solutions:

To address excessive pressure drops, clean or replace clogged filters and inspect the desiccant beds for blockages. Ensure the air pipes and hoses are appropriately sized to handle the airflow without creating restrictions. Check the heat exchangers in refrigerated dryers for fouling or scale buildup and clean them as needed. Regular maintenance of these components will improve airflow, restore efficiency, and maintain consistent air pressure throughout the system.

Frequent Desiccant Replacement (for Desiccant Dryers)

Causes:

High inlet air moisture content beyond design specifications

Inefficient regeneration process due to low heat or air pressure

Solutions:

High desiccant replacement frequency can be mitigated by reducing moisture at the inlet. Use an aftercooler or pre-filter to minimize moisture load entering the dryer. Inspect the regeneration process to ensure the heating elements or air pressure levels are sufficient for effective desiccant drying. Adjust the regeneration cycle timing to prevent premature exhaustion of the desiccant material. Regular maintenance ensures the desiccant performs optimally and lasts its intended lifespan.

Freezing of Condensate (Refrigerated Dryers)

Causes:

Low refrigerant levels or malfunctioning refrigeration system

Extremely low ambient temperature outside the dryer's design range

Solutions:

To prevent condensate freezing, monitor refrigerant levels and address any leaks in the refrigeration system. Perform routine maintenance on cooling components to ensure proper operation. If the dryer operates in extremely low ambient temperatures, consider insulating the unit or using heating systems to keep it within the recommended temperature range. These measures ensure the condensate drains correctly, preventing freezing and maintaining the dryer’s efficiency.

High Energy Consumption

Causes:

Non-cycling refrigerated dryer running continuously

Excessive demand on the dryer due to leaks or inefficient compressor operation

Solutions:

Reducing high energy consumption involves switching to a cycling refrigerated dryer, which adjusts its operation based on demand, saving energy during periods of low use. Address leaks in the compressed air system, as these increase the demand on the compressor and dryer. Optimize compressor settings to reduce unnecessary strain on the dryer. Regular maintenance and system audits ensure energy-efficient operation and identify potential issues before they escalate.

Water in Downstream Equipment

Causes:

Drain system malfunction, causing water to accumulate in the dryer

Poor maintenance or failure of moisture separators

Solutions:

Water in downstream equipment can be addressed by regularly inspecting and repairing drain systems to ensure proper condensate removal. Clean and maintain moisture separators to enhance their efficiency. Check for proper installation and alignment of these components to prevent bypassing of untreated air. Adding extra filtration or water separators downstream can further protect equipment by capturing residual moisture, ensuring consistent air quality.

Excessive Noise or Vibrations

Causes:

Loose components or mechanical failure

Inconsistent airflow due to obstructions or restrictions

Solutions:

Excessive noise or vibrations often indicate loose components or mechanical failure. Tighten bolts and connections to secure all parts. Inspect for worn bearings, damaged fans, or other mechanical issues, and replace defective parts. Check for consistent airflow to prevent obstructions causing pulsations. Addressing these issues not only resolves the noise but also enhances system efficiency, extending the lifespan of both the air dryer and the connected equipment.

Need a reliable air dryer for your compressor?

Aivyter, an expert in air compressor systems, provides advanced air dryers designed to meet your specific needs. Whether you're looking to enhance efficiency, protect your equipment, or ensure high-quality air output, Aivyter's cutting-edge solutions have you covered.

Why choose Aivyter?

Our air dryers use the latest technology to remove moisture effectively, ensuring optimal performance and extending the lifespan of your compressed air system. Trust Aivyter for precision, reliability, and quality.

Contact us today to find the perfect air dryer solution for your compressor system!

Reference Sources

Compressed air dryers

Refrigerated Air Dryers

Desiccant Air Dryers

Membrane Air Dryers

Deliquescent Air Dryers

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara