Introduction:Rotary screw air compressors are an essential piece of equipment in many industrial and manufacturing settings. These powerful machines compress air through the use of two interlocking helical screws, providing a reliable and efficient source of compressed air for various applications.

Definition and importance: A rotary screw air compressor is a type of gas compressor that uses a pair of intermeshing helical screws, known as rotors, to compress air. As the screws rotate, they trap air between them, progressively reducing the volume of the trapped air and thus increasing its pressure.

The importance of rotary screw air compressors lies in their ability to provide a continuous flow of compressed air with high efficiency and reliability. They are typically more energy-efficient than traditional piston compressors, especially in applications requiring constant air supply. Their design allows for smoother operation, less wear, and lower maintenance requirements compared to other types of compressors.

Common applications in industry and manufacturing: Rotary screw air compressors find widespread use across various industries due to their versatility and effectiveness. Some common applications include:

1. Pneumatic tools and equipment: Powering air-driven tools in manufacturing and assembly lines.

2. Spray painting: Providing consistent air pressure for automotive and industrial painting processes.

3. CNC machining: Supplying compressed air for tool changes and chip removal in computer-controlled manufacturing.

4. Packaging and bottling: Operating air-powered packaging machinery and filling systems.

5. Textile manufacturing: Powering air jet looms and other textile processing equipment.

6. Food and beverage production: Providing clean, oil-free air for product handling and packaging.

7. Pharmaceutical manufacturing: Supplying compressed air for various processes requiring sterile conditions.

8. Mining and construction: Powering pneumatic drills, jackhammers, and other heavy-duty equipment.

9. Automotive service: Operating lifts, impact wrenches, and other air-powered tools in repair shops.

10. Chemical processing: Supplying compressed air for process control and pneumatic conveying systems.

These applications highlight the crucial role that rotary screw air compressors play in modern industry and manufacturing, contributing to increased productivity, efficiency, and quality across diverse sectors.

What Is a Rotary Screw Air Compressor?

Rotary screw air compressors are advanced machines designed to produce compressed air for various industrial and commercial applications. These compressors are widely used due to their efficiency, reliability, and ability to provide a continuous supply of compressed air.

Basic operation using helical screws:

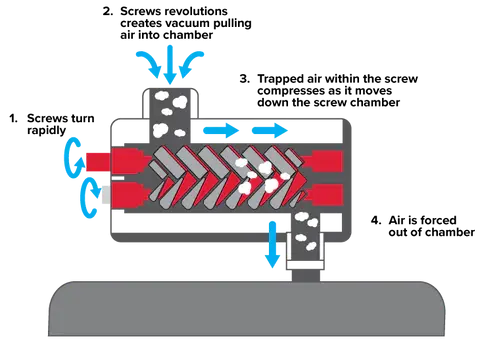

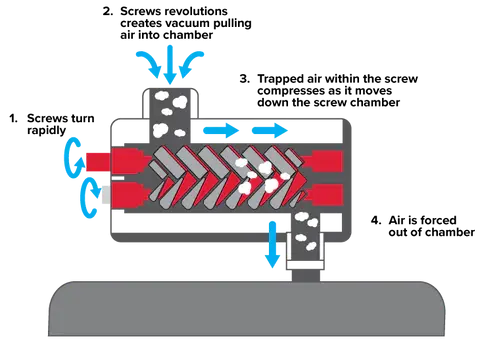

The core of a rotary screw air compressor consists of two interlocking helical screws, typically referred to as the male and female rotors. Here's how they operate:

1. Air intake: Ambient air is drawn into the compressor through an intake valve.

2. Compression: As the rotors turn, they create cavities that trap the incoming air. These cavities gradually decrease in size as the rotors rotate, compressing the trapped air.

3. Oil injection: In oil-flooded systems, oil is injected into the compression chamber to cool the air, seal gaps between the rotors, and lubricate moving parts.

4. Discharge: The compressed air, mixed with oil, is discharged from the compression chamber.

5. Separation: The air-oil mixture passes through a separation system, where the oil is removed from the compressed air.

6. Cooling and drying: The compressed air is then cooled and may pass through additional treatment systems (like dryers) before being stored or used.

Comparison with reciprocating compressors:

Rotary screw compressors offer several advantages over traditional reciprocating (piston) compressors:

1. Continuous operation: Rotary screw compressors can operate continuously, while reciprocating compressors typically require more frequent stops for cooling.

2. Smoother air delivery: Screw compressors provide a more consistent air flow with less pulsation compared to the intermittent output of reciprocating compressors.

3. Energy efficiency: At higher capacities, rotary screw compressors are generally more energy-efficient, especially when running at full load.

4. Noise level: Rotary screw compressors tend to be quieter in operation than reciprocating models.

5. Maintenance: Screw compressors have fewer moving parts, which can lead to lower maintenance requirements and costs over time.

6. Size and weight: For the same air output, rotary screw compressors are often more compact and lighter than reciprocating units.

7. Oil carryover: Rotary screw compressors typically have lower oil carryover rates, which can be crucial for applications requiring clean air.

8. Duty cycle: Screw compressors are better suited for applications requiring high duty cycles or continuous operation.

In conclusion, rotary screw air compressors offer a reliable, efficient, and versatile solution for many industrial compressed air needs, making them a popular choice across various sectors.

How Does It Work?

Rotary screw air compressors operate through a sophisticated yet efficient process that involves air intake, compression, and discharge. Understanding this process and the role of oil or alternative coatings is crucial to appreciating the functionality of these machines.

Air intake, compression, and discharge process:

1. Air intake:

The process begins as ambient air is drawn into the compressor through an intake valve.

This valve is typically equipped with an air filter to remove dust and other particles, ensuring clean air enters the compression chamber.

2. Compression:

The heart of the compressor consists of two interlocking helical screws: a male rotor (usually with convex lobes) and a female rotor (with concave flutes).

As these rotors turn, they create a series of V-shaped cavities between them.

Air enters these cavities at the intake end of the screws.

As the rotors continue to turn, the cavities move towards the discharge end, gradually decreasing in volume.

This reduction in volume results in the compression of the trapped air.

3. Discharge:

At the end of the compression process, the now-compressed air is forced out through a discharge valve.

The discharge valve is typically designed to maintain a constant pressure in the system.

From here, the compressed air may be cooled, dried, or further treated before being stored or used.

Role of oil and alternative coatings in compression:

Oil plays a crucial role in most rotary screw air compressors, though some models use alternative coatings. Here's how they function:

1. Oil-flooded compressors:

Oil is injected into the compression chamber during operation.

It serves multiple purposes: a) Cooling: Absorbs heat generated during compression. b) Sealing: Forms a barrier between the rotors and the casing, improving efficiency. c) Lubrication: Reduces friction between moving parts, extending compressor life.

1. After compression, the oil is separated from the air, cooled, and recirculated.

2. Oil-free compressors:

These use alternative coatings instead of oil.

Common coatings include PTFE (Polytetrafluoroethylene) or other specialized materials.

These coatings provide: a) A sealing function similar to oil. b) Reduced friction between the rotors and casing.

Oil-free compressors are crucial in applications requiring absolutely clean air, such as food processing or pharmaceutical manufacturing.

3. Water-injected compressors:

A less common variant that uses water instead of oil for cooling and sealing.

Beneficial in applications where even trace amounts of oil are unacceptable.

The choice between oil-flooded and oil-free (or water-injected) compressors depends on the specific application requirements, considering factors such as air purity needs, energy efficiency, and maintenance considerations.

Understanding these processes helps appreciate the efficiency and versatility of rotary screw air compressors, explaining their widespread use in various industrial applications.

Types of Rotary Screw Air Compressors

Rotary screw air compressors can be broadly categorized into two main types: oil-injected and oil-free compressors. Each type has its own unique characteristics, benefits, and applications.

Oil-Injected Compressors

Function: Oil-injected rotary screw compressors use oil in the compression chamber during operation. The oil serves multiple purposes, including cooling, sealing, and lubrication.

1. Cooling: The oil absorbs heat generated during the compression process, helping to maintain optimal operating temperatures.

2. Sealing: It forms a barrier between the rotors and the casing, improving compression efficiency by minimizing air leakage.

3. Lubrication: The oil reduces friction between moving parts, particularly the rotors, extending the compressor's lifespan.

Benefits:

1. Higher efficiency: The oil's sealing properties allow for better compression ratios and energy efficiency.

2. Lower operating temperatures: Oil cooling helps maintain lower temperatures, reducing wear on components.

3. Lower initial cost: Oil-injected models are generally less expensive than oil-free alternatives.

4. Longer lifespan: Reduced friction leads to less wear on components, potentially extending the compressor's operational life.

5. Quieter operation: Oil helps dampen noise, resulting in quieter performance compared to oil-free models.

Applications: Oil-injected compressors are widely used in various industries where trace amounts of oil in the compressed air are acceptable. Common applications include:

1. General manufacturing and assembly lines

2. Automotive repair shops

3. Construction sites

4. Woodworking and furniture manufacturing

5. Metalworking and machining operations

6. Textile industry

7. Mining operations

Oil-Free Compressors

Function: Oil-free rotary screw compressors operate without oil in the compression chamber. Instead, they use special coatings on the rotors and advanced sealing technologies to achieve compression.

1. Air compression: The rotors are precisely engineered to compress air without the need for oil sealing.

2. Cooling: These compressors often use air or water cooling systems to manage heat.

3. Sealing: Special coatings and design features maintain the seal between rotors and the casing.

Benefits:

1. Clean air output: With no oil in the compression chamber, there's no risk of oil contamination in the compressed air.

2. Lower maintenance costs: No need for oil changes or oil filtration systems.

3. Environmentally friendly: Eliminates the risk of oil disposal and potential environmental contamination.

4. Consistent air quality: Provides reliable, oil-free air throughout the compressor's lifetime.

5. Compliance with stringent air quality standards: Meets requirements for industries with zero tolerance for oil contamination.

Applications: Oil-free compressors are essential in industries and applications where air purity is critical:

1. Food and beverage production

2. Pharmaceutical manufacturing

3. Electronics and semiconductor production

4. Medical and dental facilities

5. Textile industry (for specialized processes)

6. Chemical processing

7. Spray painting in automotive and other industries

8. Brewing and bottling operations

Both oil-injected and oil-free rotary screw compressors have their place in the industrial world. The choice between them depends on the specific requirements of the application, including air quality needs, energy efficiency considerations, initial investment capacity, and long-term operational costs. Understanding these differences allows businesses to select the most appropriate type of rotary screw air compressor for their unique needs.

Components of Rotary Screw Air Compressors

Rotary screw air compressors consist of several key components that work together to provide efficient and reliable compressed air. Understanding these components is crucial for proper operation, maintenance, and troubleshooting.

Air-End: Rotors, valves, bearings

The air-end is the heart of a rotary screw compressor, responsible for the actual compression of air.

1. Rotors:

Usually consist of a male (convex lobes) and a female (concave flutes) rotor

Precision-machined to ensure tight tolerances and efficient compression

Materials often include steel with specialized coatings for durability and efficiency

2. Valves:

Inlet valve: Controls air intake into the compression chamber

Minimum pressure valve: Maintains minimum system pressure for proper oil circulation

Check valve: Prevents backflow of compressed air

3. Bearings:

Support the rotors and absorb radial and axial loads

Types include roller bearings, ball bearings, or journal bearings

Critical for maintaining proper rotor alignment and efficiency

Motor and Control System: Motor types, control mechanisms

The motor provides power to the compressor, while the control system manages its operation.

1. Motor types:

Induction motors: Most common, reliable, and cost-effective

Permanent magnet motors: Higher efficiency, especially at partial loads

Variable speed drive (VSD) motors: Allow for adjustable speed to match air demand

2. Control mechanisms:

Load/unload control: Alternates between full load and idle states

Modulation control: Adjusts inlet valve to match air demand

Variable speed control: Adjusts motor speed to precisely match air demand

Networked control systems: Manage multiple compressors for optimal efficiency

Air Compressor Filters: Intake, inline, and oil filters

Filters are crucial for maintaining air quality and protecting the compressor components.

1. Intake filters:

Remove dust and particulates from incoming air

Protect internal components from contamination

2. Inline filters:

Installed in the compressed air line

Remove moisture, oil, and particles from the compressed air

Different grades available for various air quality requirements

3. Oil filters:

Clean the oil before it's recirculated in oil-injected compressors

Crucial for maintaining oil quality and protecting internal components

Cooling System: Air-cooled vs. water-cooled

Cooling systems manage the heat generated during compression.

1. Air-cooled systems:

Use fans to force air over cooling fins

Simpler design, easier to install and maintain

Suitable for most applications with moderate ambient temperatures

2. Water-cooled systems:

Use water or coolant circulated through a heat exchanger

More efficient, especially in high-temperature environments

Require access to a suitable water supply and proper water treatment

Oil-Injection System: Oil sump, filters, separators

For oil-injected compressors, the oil system is crucial for operation and efficiency.

1. Oil sump:

Reservoir for storing and cooling the oil

Often integrated with the air-end housing

2. Oil filters:

Remove contaminants from the oil

Critical for protecting internal components and maintaining efficiency

3. Oil separators:

Remove oil from the compressed air after compression

Typically use a combination of mechanical separation and coalescing filters

Crucial for air quality and oil recovery

Each of these components plays a vital role in the operation of a rotary screw air compressor. Proper understanding, maintenance, and selection of these components ensure optimal performance, efficiency, and longevity of the compressor system.

Rotary Screw Air Compressor Accessories

To optimize the performance and efficiency of rotary screw air compressors, various accessories are typically employed. These accessories can improve compressed air quality, increase system reliability, and extend equipment lifespan. Here are three important accessories commonly used:

Compressed Air Dryers: Refrigerated vs. desiccant

Compressed air dryers are crucial for removing moisture from compressed air. Moisture can lead to pipeline corrosion, tool damage, and affect final product quality. There are two main types of dryers:

Refrigerated dryers:

1. Operation principle: Cools air below its dew point to condense moisture

2. Advantages:

Lower initial cost

Lower operating costs

Suitable for most industrial applications

3. Disadvantages:

Cannot achieve extremely low dew points

4. Applications: General industrial use, such as automotive repair, painting, etc.

Desiccant dryers:

1. Operation principle: Uses moisture-absorbing materials (e.g., activated alumina) to remove water vapor

2. Advantages:

Can achieve very low dew points (down to -40°C or lower)

Suitable for applications requiring extremely dry air

3. Disadvantages:

Higher initial and operating costs

Requires periodic replacement or regeneration of the desiccant

4. Applications: Pharmaceuticals, food processing, electronics manufacturing, etc.

Choosing the appropriate dryer type depends on specific application requirements, desired air quality, and operational cost considerations.

Air Receiver Tank

Air receiver tanks are important components in rotary screw air compressor systems, serving several key functions:

1. Compressed air storage:

Provides a buffer for compressed air, meeting high short-term demands

Reduces compressor start-stop frequency, extending equipment life

2. System pressure stabilization:

Balances supply and demand fluctuations, maintaining stable system pressure

Improves efficiency and longevity of downstream equipment

3. Cooling and condensation:

Provides additional cooling time for compressed air

Allows further condensation of moisture and oil vapors, improving air quality

4. Pulsation dampening:

Reduces pressure pulsations from the compressor

Provides smoother air flow

Selecting the right size air receiver tank is crucial for overall system efficiency. Tank size typically depends on compressor output, air demand patterns, and system pressure requirements.

Drain Valves

Drain valves are devices used to remove condensate from compressed air systems. They are critical for maintaining system performance and protecting downstream equipment. Main types include:

1. Manual drain valves:

Require operators to open the valve periodically to drain water

Advantages: Simple, low cost

Disadvantages: Can be overlooked, potentially leading to water accumulation issues

2. Timer-operated drain valves:

Automatically open at preset time intervals

Advantages: No manual intervention required, reliable operation

Disadvantages: May open when draining is unnecessary, wasting compressed air

3. Electronic level-sensing drain valves:

Use sensors to detect condensate levels and drain only when necessary

Advantages: Efficient, energy-saving, minimizes compressed air loss

Disadvantages: Higher initial cost, may require more maintenance

4. Float-operated drain valves:

Use a float mechanism to automatically drain when water reaches a certain level

Advantages: Simple and reliable, requires no external power

Disadvantages: Can be affected by dirt, requires periodic cleaning

Choosing the appropriate drain valve type depends on system size, environmental conditions, maintenance capabilities, and budget considerations. Proper condensate management can significantly improve system efficiency, reduce maintenance costs, and extend equipment life.

These accessories, when used in conjunction with rotary screw air compressors, can significantly enhance the performance and reliability of the entire compressed air system. Selecting the right combination of accessories is crucial for optimizing system operation, reducing operational costs, and ensuring compressed air quality.

Choosing a Rotary Screw Air Compressor

Selecting the right rotary screw air compressor for your needs is crucial for operational efficiency and cost-effectiveness. Several key factors should be considered when making this decision:

Demand size: The compressor's capacity should match your air demand requirements. To determine this:

· Calculate your current compressed air usage

· Estimate future needs for potential expansion

· Consider peak demand periods

Oversizing can lead to unnecessary energy consumption, while undersizing may result in insufficient air supply. Aim for a compressor that can handle your peak demand with some additional capacity for flexibility.

Lifetime cost: When evaluating rotary screw air compressors, consider the total cost of ownership, not just the initial purchase price. This includes:

· Initial investment

· Energy costs (typically 70-80% of lifetime costs)

· Maintenance expenses

· Replacement parts

· Potential downtime costs

Energy-efficient models may have higher upfront costs but can provide significant savings over time. Variable speed drive (VSD) compressors can be particularly cost-effective for applications with fluctuating demand.

Noise levels: Noise considerations are important, especially in work environments where excessive noise can be disruptive or potentially harmful. Factors to consider include:

· Compressor design (some models are specifically engineered for quieter operation)

· Enclosures or sound-attenuating options

· Installation location within your facility

Many modern rotary screw compressors operate at lower noise levels compared to reciprocating models, but it's still important to check the decibel ratings and consider any additional sound-reduction measures if needed.

Air purity: The required air quality depends on your specific application. Consider:

· Industry standards or regulations for air purity

· Sensitivity of your processes or equipment to contaminants

· Potential consequences of air contamination

For applications requiring high air purity, such as food processing or pharmaceuticals, you may need to invest in oil-free compressors or additional air treatment equipment like filters and dryers.

Usage patterns: Understanding your usage patterns is crucial for selecting the most appropriate compressor:

· Continuous vs. intermittent operation

· Steady demand vs. fluctuating needs

· Operating hours per day/week

For variable demand, consider VSD compressors that can adjust output to match changing needs. For continuous operation, focus on models designed for high duty cycles and reliability.

Additional considerations:

· Space constraints: Ensure the compressor fits in your available space

· Environmental conditions: Consider ambient temperature, humidity, and air quality

· Maintenance requirements: Evaluate the ease of maintenance and availability of service support

· Compatibility with existing systems: If integrating with current equipment, ensure compatibility

· Future scalability: Consider potential for future expansion or changing needs

By carefully evaluating these factors, you can select a rotary screw air compressor that not only meets your current needs but also provides long-term value and efficiency for your operations. Remember that consulting with compressed air specialists can provide valuable insights tailored to your specific situation.

Advantages and Disadvantages of Rotary Screw Air Compressors

Rotary screw air compressors have become increasingly popular in various industries due to their unique characteristics. However, like any technology, they come with both benefits and drawbacks. Understanding these can help in making informed decisions about their adoption and use.

Benefits: Efficiency, reliability, air quality, and space savings

1.Efficiency:

High volumetric efficiency, typically 70-90%

Consistent air output, even under varying conditions

Energy-efficient operation, especially with variable speed drive (VSD) models

Can operate at 100% duty cycle, suitable for continuous operation

2. Reliability:

Fewer moving parts compared to reciprocating compressors

Designed for long operational life with proper maintenance

Consistent performance over time

Lower vibration levels, reducing wear and tear on components

3. Air quality:

Oil-injected models provide better air quality than many reciprocating compressors

Oil-free models available for applications requiring ultra-clean air

Steady airflow with minimal pulsation

Lower operating temperatures, reducing thermal degradation of lubricants

4. Space savings:

Compact design, especially compared to equivalent capacity reciprocating compressors

Vertical configurations available for further space optimization

Integrated designs with dryers and filters can save additional floor space

Quieter operation allows for installation closer to point of use

Drawbacks: Initial cost, maintenance complexity, environmental considerations

1. Initial cost:

Higher upfront investment compared to reciprocating compressors

Specialized components can be more expensive

Additional costs for air treatment equipment may be necessary

VSD models have higher initial costs, though they often provide long-term savings

2. Maintenance complexity:

Requires specialized knowledge and tools for maintenance and repairs

More complex internal components compared to simpler compressor designs

Regular maintenance is crucial for optimal performance and longevity

Potential for higher repair costs if not properly maintained

3. Environmental considerations:

Oil-injected models require proper oil disposal and management

Potential for oil contamination if not properly maintained

Energy consumption can be significant, impacting carbon footprint

Noise pollution, though generally less than reciprocating compressors, can still be a concern

Additional considerations:

1. Sensitivity to inlet conditions:

Performance can be affected by changes in inlet air temperature and humidity

May require additional filtration in dusty environments

2. Heat recovery:

While not a drawback, the significant heat generated during compression can be harnessed for other processes, but requires additional investment

3. Minimum pressure ratio:

Rotary screw compressors typically have a minimum pressure ratio, which may not be suitable for very low-pressure applications

4. Sizing considerations:

Oversized units can lead to inefficient operation and increased wear

Undersized units may not meet air demand, leading to system issues

5. Training requirements:

Operators and maintenance staff may require specialized training

In conclusion, rotary screw air compressors offer significant advantages in terms of efficiency, reliability, air quality, and space savings. These benefits make them ideal for many industrial applications, especially those requiring continuous operation or high air quality. However, the higher initial cost, maintenance complexity, and environmental considerations must be carefully weighed against these benefits. Proper sizing, regular maintenance, and consideration of the specific application requirements are crucial for maximizing the advantages while mitigating the drawbacks of rotary screw air compressors.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara